In the production of drilling equipment for petroleum machinery, there are numerous types and complex structures of drilling rig frame components. By introducing the LE robotic welding machine, the production efficiency has been successfully increased, making it a typical case for welding operations on drilling rig frame components.

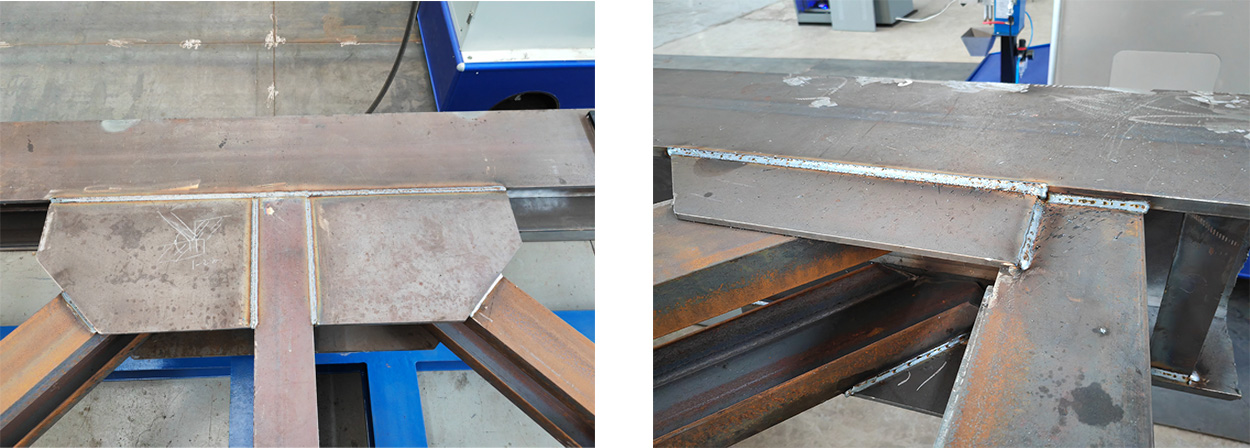

In the production of drilling rig frames, various welding methods are involved in the manufacturing process, such as T-joint vertical welding seams, plate butt joint vertical welding interlayer seams, plate butt joint horizontal welding seams, and other diverse and complex welding operations. These are constrained by the instability and inefficiency of manual operations, making it challenging to ensure welding quality and failing to meet the strict requirements of modern drilling projects for efficiency and quality.

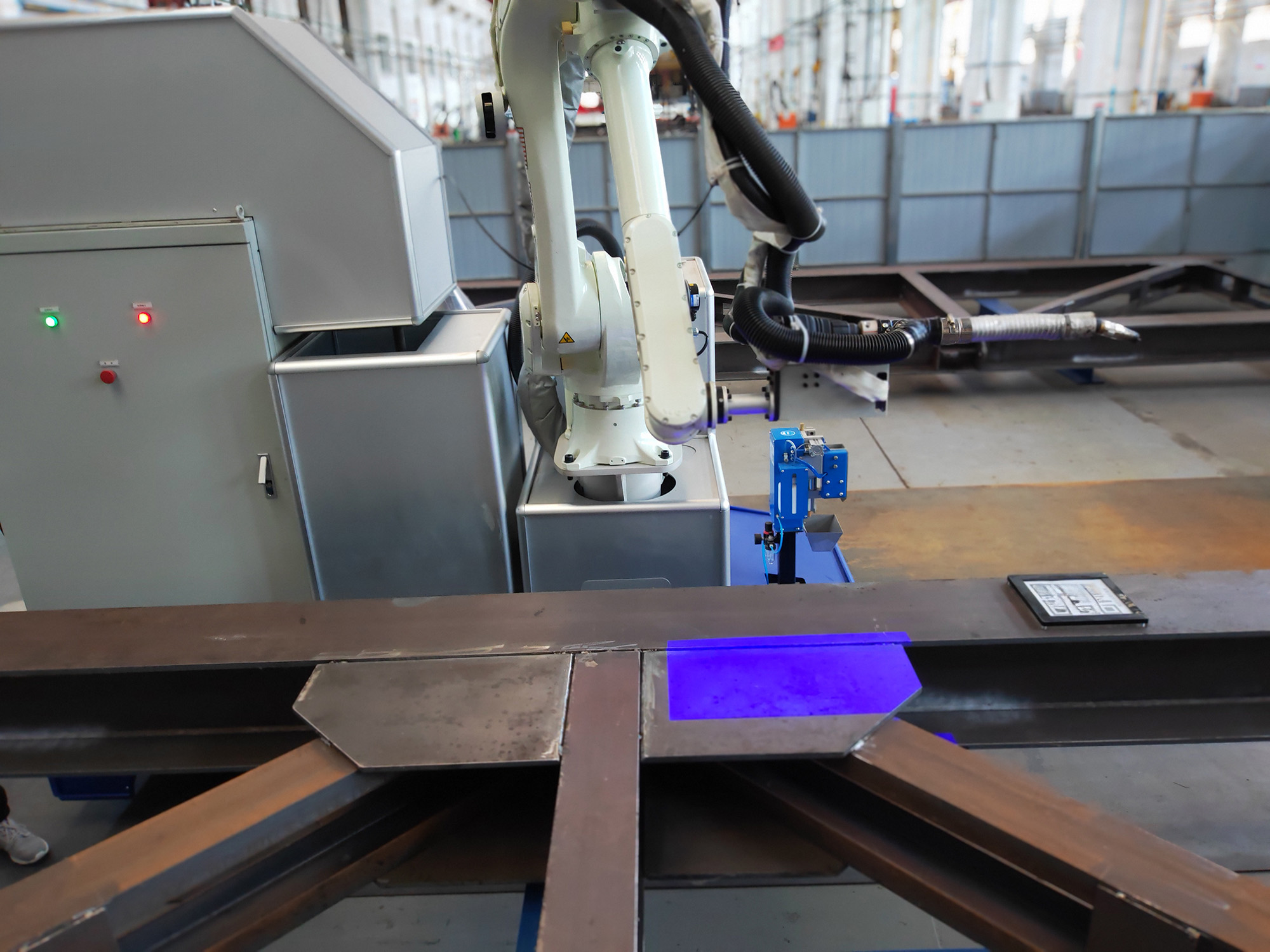

Adopt the LE "Navigator" welding robot with integrated intelligent 3D vision and flexible welding technology.

The robot is equipped with mecanum wheels, providing omnidirectional movement capabilities, intelligent walking, and autonomous navigation functions to meet flexible operational needs.

The robot automatically performs welding operations, with a one-click start for convenient operation, eliminating the need for manual programming, teaching, and welding process formulation.

During the operation, the robot can automatically adjust the position and posture of the welding gun, achieving functions such as workpiece positioning, seam tracking, and accurate seam tracking capability (accuracy less than 1mm).

The Navigator can also achieve remote monitoring and multi-device management, improving efficiency and reducing the need for manual intervention.

Robotic welding technology has successfully improved welding accuracy and efficiency, surpassing industry standards in welding reach rates.]

Effectively reduces the labor intensity of workers, optimizes welding quality, reduces operational risks, enhances productivity, and lowers production costs.

Has a profound impact on enhancing the production efficiency and welding operation quality of the entire petroleum machinery production industry.

Contact