From the perspective of quality and efficiency, new quality productive forces signify an enhancement in production processes and product quality, as well as a leap in the industrial and value chains." Innovation never ceases, and the classic never becomes outdated.

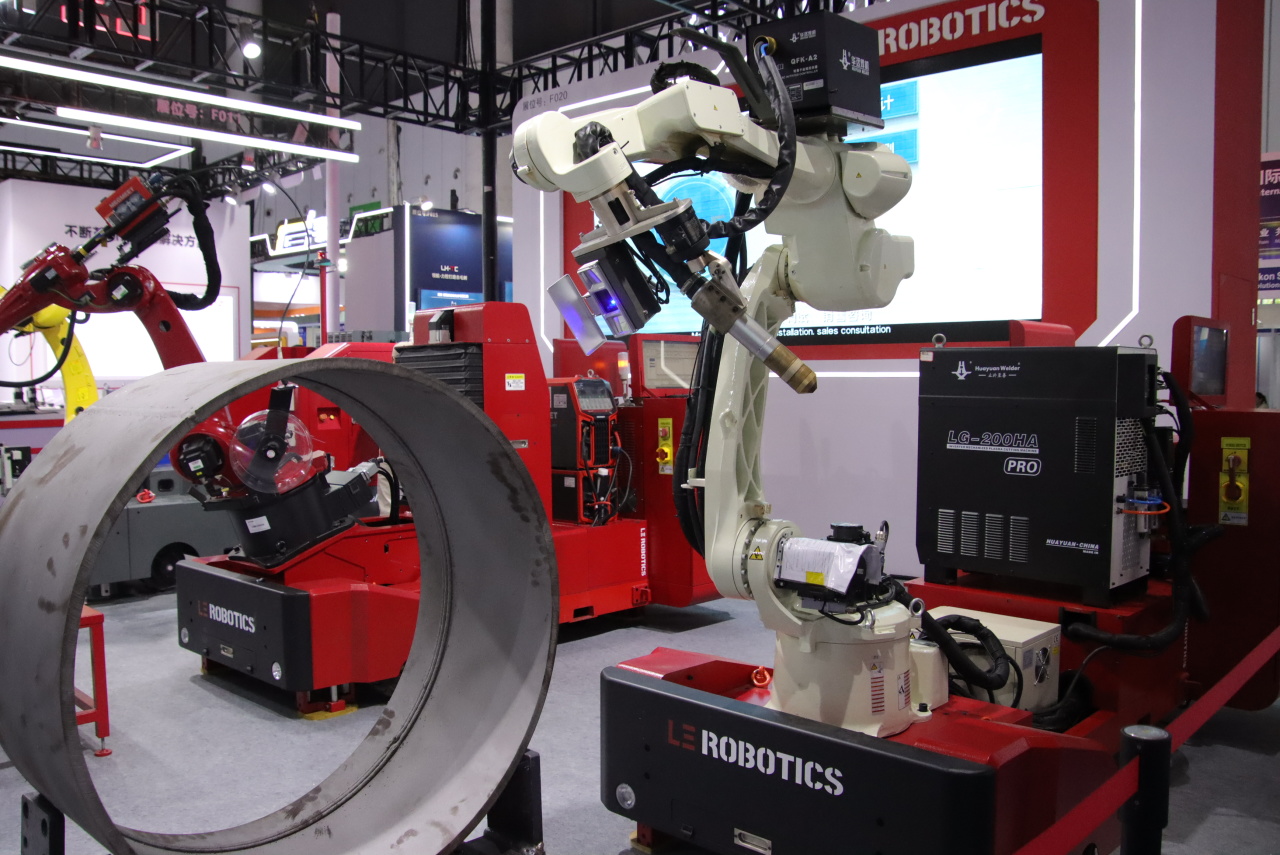

On April 24th, the 2024 Chengdu International Industrial Expo was held at the Western China International Expo City. Representing the local robot team from Chengdu, LE Robotic Welder (Booth Number: Hall 14, F020) made an appearance at this grand event with the theme "Innovative Intelligence, Welding the Future," showcasing a complete set of automated and intelligent welding and cutting solutions! When LE Robotic Welder encounters "new quality productive forces," what kind of sparks of wisdom will be ignited at this exhibition?

Enhancing Quality with the New

LE Robotic Welder Opens Up New Horizons in Industrial Smart Manufacturing

From steel structure welding and metal cutting to one-stop intelligent solutions, LE Robotic Welder, in its continuous and innovative development, takes flexible production and intelligent empowerment as its core. It constantly draws innovative 'inspiration' from the market to continuously empower industrial intelligent manufacturing, truly transforming technological innovation into a new driving force for industrial development.

At this Chengdu Industrial Expo, LE Robotic Welder focused on intelligent and flexible production, showcasing groundbreaking innovative solutions and presenting a new set of answers for the upgrade of the smart manufacturing industry.

Part.01

IntelliMover Welder

In the field of mobile robotics, the IntelliMover Welder showcased the application of SLAM (Simultaneous Localization and Mapping) autonomous navigation technology in welding. By integrating autonomous navigation, robotic control technology, AI (Artificial Intelligence), and the RX process database, the LE Robotic Welder's IntelliMover is capable of operating without human intervention and can act autonomously in various industrial environments.

运用特点:

Integrated 'Foot-Arm-Hand-Eye-Brain' Control: Foot - SLAM navigation and positioning combined with vision and LiDAR; Arm - Perfect coordination of six joints, agile and flexible; Hand - Execution of welding process library data; Eye - Real-time scene recognition with 3D vision; Brain - Real-time coordinated control of foot, arm, hand, and eye.

Intelligent Workpiece Perception: 3D vision for programming-free and teaching-free operation, AI gesture + voice input to reduce operational barriers.

Functional Safety, Shared Space for Humans and Machines: Autonomous navigation and obstacle avoidance, collaborative operation of multiple devices.

Intelligent Environmental Perception: Automated guidance, precise positioning with vision, strong versatility.

Part.02

WindRunner Cutter)

In fields such as construction machinery, mining machinery, and shipbuilding for offshore engineering, there is a need to address complex and variable cutting requirements to enhance product and cutting quality. The WindRunner Welder (Cutting Model) combines mobility and flexibility, enabling it to adapt to workpieces of different sizes and shapes.

Application Features:

Power Configuration: Differential axle power system combined with remote control driving capability.

No Programming, No Teaching Required: No experience in robot operation needed, no foundation in welding and cutting processes, quick to master the entire operation process.

Intelligent Workpiece Perception: Composite vision technology of 3D panoramic and 3D laser line scanning, the organic integration of 3D cloud data acquisition system and core processing algorithms for precise 3D scene recognition.

Axis Linkage Control Method: Capable of achieving rotation, swinging, and cutting of any contour curve.

Part.03

WindRunner Welder (Lift Model)

风行者(升降款)车身搭载的差速桥动力系统优化了机械性,确保产品稳定性和机动性,从而为制造车间、自动化物料处理和复杂的定制焊接应用等场景提供了完整的解决方案。

Application Features:

Power Configuration: A differential axle power system combined with remote control driving capability.

No Programming, No Teaching Required: No prior experience in robot operation is needed; no foundation in welding or cutting processes is necessary for quick mastery of the entire operation process.

Intelligent Workpiece Perception: A composite vision technology featuring 3D panoramic imaging and 3D laser line scanning, with an organic integration of a 3D cloud data acquisition system and core processing algorithms for precise 3D scene recognition.

Axis Linkage Control Method: Enables rotation, swinging, and cutting of any contour curve for notching.

Media Spotlight

LE Robotic Welder Soars in the Field of Intelligent Manufacturing

"As an outstanding representative of the Sichuan robot consortium, LE Robotic Welder, guided by the country's major strategic needs, has always adhered to technological innovation as its core, deeply cultivating the field of steel structure, and continuously accumulating rich experience and overcoming technical challenges. At this exhibition, LE Robotic Welder fully demonstrated its strong technical strength and innovative achievements in the field of robotics.

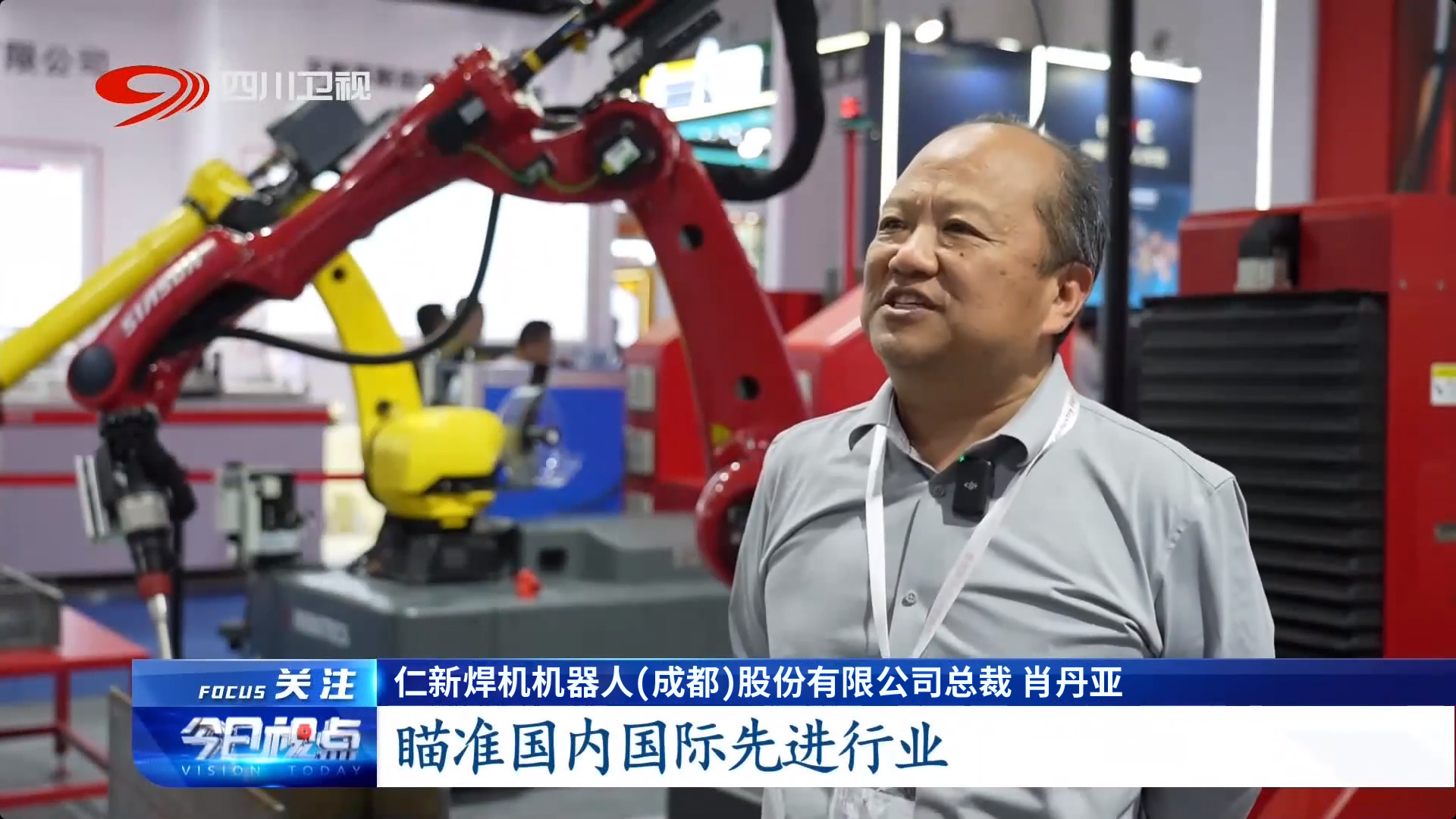

During the exhibition, Xiao Danyang, President of LE Robotic Welder, was interviewed by Sichuan TV. He introduced the company's innovative achievements and technical strength to the media and provided a detailed analysis of the technical details of LE Robotic Welder. Xiao Danyang stated that LE Robotic Welder has the characteristics of being efficient, accurate, and stable, capable of providing users with excellent welding solutions. It reduces operational costs while improving operational efficiency, thus offering a highly effective solution for the intelligent transformation of the manufacturing industry.

Media outlets such as China Economic Network, China News Service, Sichuan News Network, Sichuan Daily, and Chengdu Political Affairs have also conducted in-depth reports on LE Robotic Welder. These reports not only introduced in detail the technical features and advantages of LE Robotic Welder but also deeply analyzed its tremendous potential in promoting technological progress and industrial upgrading in the industry. The media generally believes that LE Robotic Welder will bring revolutionary changes to the field of intelligent manufacturing and promote the industry to a higher level of development.

According to incomplete statistics, the online exposure of LE Robotic Welder at this exhibition has exceeded one million times. This achievement not only demonstrates the outstanding strength of LE Robotic Welder in terms of technological innovation and product quality but also reflects the market and users' high recognition and trust in LE Robotic Welder.

Extraordinarily Popular

The booth becomes the industry's focus, attracting widespread attention

"At the exhibition site, LE Robotic Welder captivated the audience with an impressive product demonstration, showcasing the product's efficiency, stability, and intelligence. The entire demonstration attracted the attention of many onlookers, who actively engaged in interactive experiences with the robot, personally feeling the unique operation method and precision of LE Robotic Welder. The atmosphere at the venue was very lively.

During the exhibition, the technical strength of LE Robotic Welder won widespread acclaim from industry experts and a large number of customers. They fully affirmed the product's excellent performance and unique innovative capabilities, showing a strong willingness to cooperate.

In the process of sales consulting and order signing, LE Robotic Welder achieved remarkable results, injecting new momentum into the company's future stable development. This significant achievement not only highlights the competitiveness of LE Robotic Welder in the domestic market but also further confirms its influence and market position on the international stage.

Facing the future, LE Robotic Welder will continue to adhere to a rigorous and stable business philosophy, continuously advancing technological innovation and service optimization to meet the growing needs of customers and strive to maintain a leading position in the global market competition.

Driven by the technological revolution, industries from all sectors are gradually integrating into the vast realm of the industrial internet, and no company can stand alone in this interconnected world. Looking ahead, LE Robotic Welder will unswervingly enhance its innovative resilience and continue to deliver the fruits of technological innovation to the subtleties of various industries. With our own development and innovation, we will help all sectors embark on new journeys, empower a myriad of industries to move towards the 'new', and improve efficiency with 'quality'.

——END——

Contact