In the traditional manufacturing process of large non-standard structural parts, manual welding has become one of the key factors limiting the further improvement of production quality and efficiency. For the multi-layer and multi-pass welding process of thick plates, processes such as preheating, root pass cleaning, and post-weld grinding are required. These are labor-intensive and cumbersome, with extremely high demands on the operator's proficiency and skill level, severely restricting the development of the industry.

In recent years, with the advancement of efficient welding methods and flexible welding systems, the industry has reached a consensus on using welding robots with good stability and high efficiency to improve the level of automation.

However, traditional welding robot technology struggles to meet industry demands. Although some degree of automation in the welding process can be achieved through manual teaching, starting point positioning, arc tracking, and laser tracking technologies, simple teaching programming methods are inefficient and have gradually been phased out. Laser tracking is currently mainly used for single-pass welds and requires manual assistance, making it difficult to popularize.

Therefore, to improve the current situation where large structural parts mainly rely on manual welding, LE Robotics has independently developed intelligent welding advanced products with 3D vision technology and SLAM autonomous navigation technology. These products achieve autonomous intelligent full automatic welding of medium-thick plate structural parts, enhancing the welding quality of products and improving production efficiency.

3D Vision + SLAM Autonomous Navigation Technology Achievements

Research and Development Background

Our research has revealed that traditional robotic welding often requires manual teaching before welding, which consumes a significant amount of time and cannot guarantee the completion of production tasks as expected. Traditional robots demand extremely high precision in component positioning, and non-standard components necessitate the production of a variety of different types of jigs and fixtures for clamping and positioning. The cost of these jigs and the labor cost of clamping are also the main pain points that hinder the automation of large non-standard components.

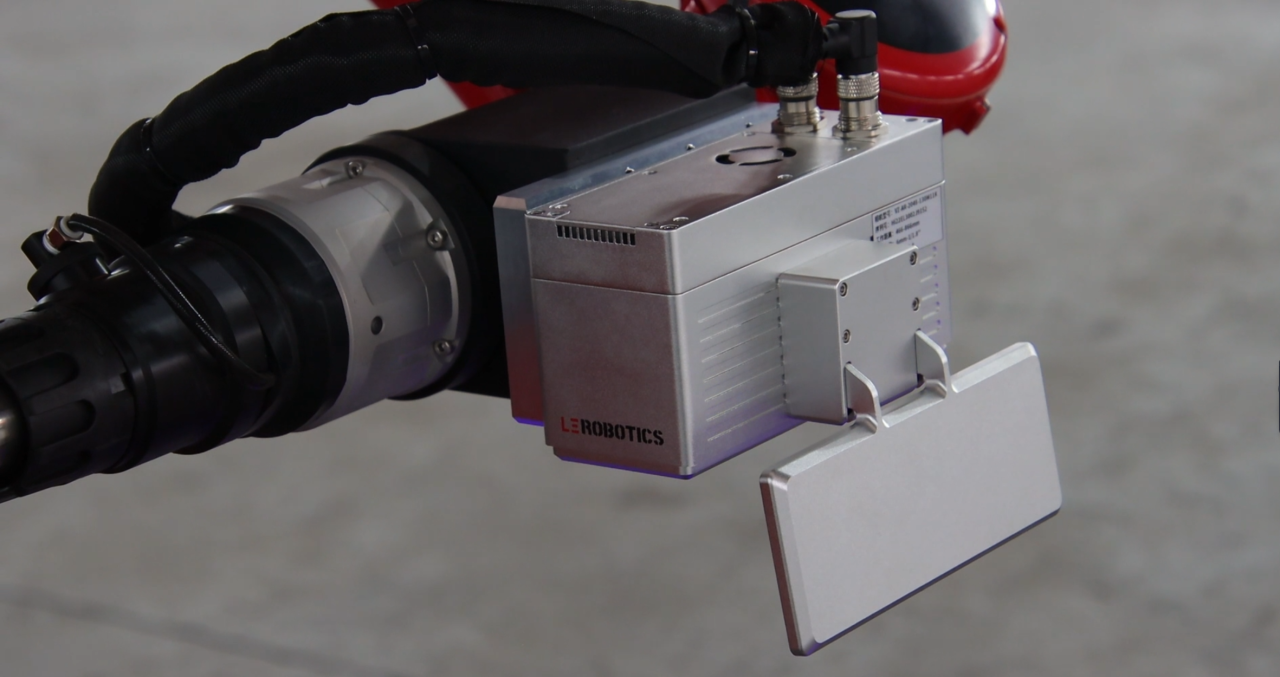

(▲LE Robotics Welding Machine Products)

LE Robotics Welding Machine Technical Achievements

The LE Robotics Welding Machine, equipped with 3D vision and autonomous navigation technology, eliminates the need for the pre-weld teaching process required by traditional robotic welding. Regardless of how the workpieces are positioned, it can achieve fully automatic continuous welding for small batch, multi-variety non-standard workpieces.

(▲LE Robotics Welding Machine Products)

Achievements of 3D Vision Technology in Welding

The 3D vision technology of the LE Robotics Welding Machine is capable of autonomously recognizing the position of the weld seam on workpieces. It uses laser vision to independently locate the weld seam, automatically identify the shape of the bevel, retrieve welding process parameters for different layers and passes, and can automatically generate multi-layer and multi-pass welding process paths, continuously and automatically tracking and completing the welding of the components.

(▲LE Robotics Welding Machine Products)

Achievements of SLAM Autonomous Navigation Technology in Welding

The advanced autonomous mobility of the LE Robotics Welding Machine has revolutionized the traditional welding process, allowing enterprises to be no longer reliant on complex jigs and fixtures for positioning. It enables operators to freely place different types of components within the operational space. Since the robot can intelligently recognize and move to the workpiece location, even if the components are not evenly placed, it will not affect the welding quality, thereby significantly reducing the frequent intervention time of personnel in the loading and unloading process.

This innovative technology effectively reduces the reliance on high-precision assembly and specialized fixtures, enhances the flexibility and efficiency of the welding process, and achieves a more efficient and automated production workflow.

(▲LE Robotics Welding Machine Products)

Achievements of the RX Weld Seam Process Library in Welding

The RX weld seam process library on the LE Robotics Welding Machine can intelligently recognize the type of weld seam on the workpiece and automatically retrieve and apply the most suitable welding process parameters, ensuring the quality of each weld seam.

When performing automatic multi-layer and multi-pass welding tasks, the robotic welding machine can not only automatically adjust the angle and offset of the welding torch to adapt to the welding requirements of different layers, but also seamlessly switch to the next welding program without manual intervention after completing the first pass. This intelligent continuous operation process helps enterprises to improve production efficiency, reduce production cycles, and brings revolutionary efficiency improvements to the manufacturing industry.

(▲LE Robotics Welding Machine Products)

Additionally, in terms of automatic torch cleaning and wire cutting, the LE Robotics Welding Machine is equipped with automatic positioning for torch cleaning and wire cutting functions. During the welding process, it quickly and automatically positions itself to the cleaning device according to the parameter settings to perform automatic torch cleaning and wire cutting. It then swiftly returns to the position before cleaning, achieving an automated torch cleaning effect.

(▲LE Robotics Welding Machine Products)

Choosing LE Robotics Welding Machines = Choosing Intelligence and Efficiency

(▲LE Robotics Welding Machine Production Park)

The successful application of 3D vision and autonomous navigation technology in LE Robotics Welding Machines has filled the gap in the application of robotic vision technology in industries such as large-scale engineering machinery, construction machinery, and wind power equipment. Moreover, its wide range of technical applicability holds great reference value within the industry. Especially for the fully automatic welding operation of various types of non-standard large components, LE Robotics Welding Machines can provide you with practical and highly intelligent welding solutions. These solutions help to enhance production efficiency and improve welding quality, making LE Robotics Welding Machines your best partner on the road to success!

——END——

Contact