Full - stack Embodied Intelligence Technology: By integrating 3D vision, SLAM autonomous navigation, and AI algorithms, it breaks through the limitations of traditional robots that rely on pre - set programs. It enables autonomous welding of complex and irregular workpieces without programming.

Adaptive Process System: Through multi - modal perception technology, it monitors the molten pool state and arc data in real - time. Combined with reinforcement learning algorithms, it dynamically optimizes welding parameters, significantly improving the stability of weld quality and process adaptability.

Intelligent Ecosystem Collaborative Architecture: It constructs an open process library and a multi - robot collaborative system, promoting the transformation of environmental protection equipment manufacturing towards a full - process digital and zero - human - intervention intelligent manufacturing paradigm.

As a national-level specialized, refined, distinctive, and innovative "little giant" enterprise, Huaxia Bishui has been deeply involved in environmental protection for 17 years, covering five major fields including wastewater, waste gas, solid waste, physical pollution, and ecological restoration, and has developed the service capabilities for the entire industrial chain. Its R & D team has collaborated with top institutions such as the Chinese Academy of Sciences and obtained over a hundred patents. In particular, it leads the world in the treatment of high-concentration industrial wastewater.

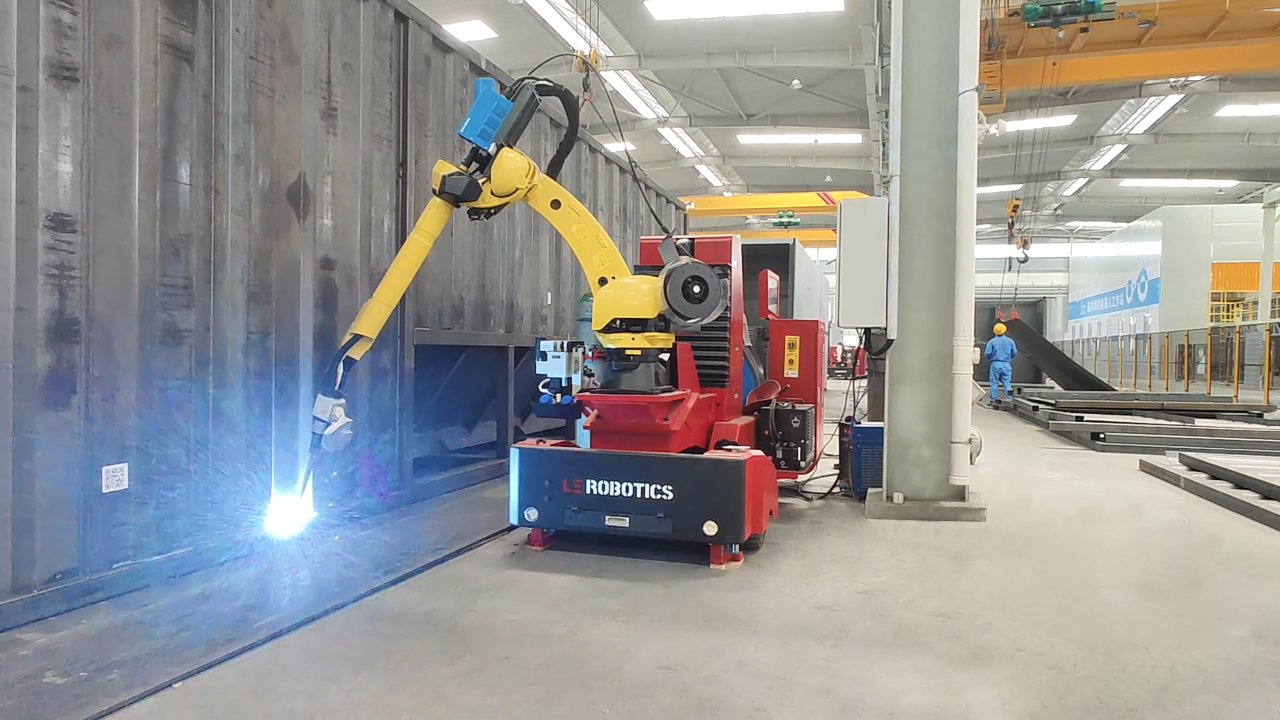

LE Robotics, as a leader in industrial intelligent equipment, relies on embodied intelligence technology, integrating 3D vision, SLAM autonomous navigation, and AI algorithms. It endows robots with the abilities of autonomous perception and decision-making, enabling them to dynamically plan paths for high-precision operations. Its technology breaks through the limitations of traditional robots that rely on pre-set programs, significantly improving the welding efficiency and flexibility of special-shaped parts of environmental protection equipment. Moreover, the high consistency of welding quality guarantees the high-quality delivery of projects for environmental protection equipment enterprises.

The two parties have joined hands to tackle the complex welding challenges of environmental protection equipment and jointly create a demonstration model for intelligent manufacturing.

Hu Haojie

Chief Executive Officer (CEO) of LE Robotics

Facing the dual challenges of the global shortage of welders and the increasing complexity of environmental protection equipment manufacturing, our innovatively developed embodied intelligence welding and cutting robots, guided by 3D vision and with AI autonomous decision-making capabilities, have completely overturned the limitations of traditional robots that rely on pre-set programs. Whether it is the programming-free welding of special-shaped workpieces or the intelligent factory with multi-robot collaboration, LE Robotics is leveraging its full-stack technological capabilities to drive the transformation of environmental protection equipment manufacturing towards intelligent manufacturing characterized by "zero human intervention and full-process adaptability". This is creating dual value in terms of both efficiency and quality for our customers.

The Flange of the Storage Tank Body: Welding Challenges of Double Arc Surfaces

The corrugated parts of the integrated corrugated plate box require a very high frequency of welding. Traditional robotic welding is time - and labor - consuming as it needs to go through the teaching process. While manual welding can ensure the quality, it is difficult to meet the needs of large - scale production due to its low efficiency.

LE Robotics adopts 3D vision guidance and AI path planning technology. By rapidly scanning the three - dimensional contour of the workpiece, it can automatically generate the optimal welding path without manual teaching, precisely matching the complex trajectory of the corrugated parts.

The welding efficiency has been improved by more than three times, completely solving the teaching problem of complex workpieces. At the same time, it ensures the stability of weld quality, providing strong support for large - scale production.

The Conical Workpieces of the Harvesting Bin: Welding Challenges in Complex Spaces

Both the storage tank body and the flange adopt an arc design. When using traditional robots to weld the butt welds of the double curved surfaces, it is necessary to teach point by point, which is time-consuming and labor-intensive. Moreover, the weld quality fluctuates greatly, making it difficult to meet the high-precision requirements.

LE Robotics has introduced an adaptive parameter adjustment system. Based on the arc data and molten pool state collected in real time, the AI algorithm dynamically matches the optimal welding parameters, automatically adapting to the welding requirements of the double arc surfaces.

The first-time qualification rate of the weld seams has been significantly increased, the welding time has been greatly shortened, and the quality stability has reached the international advanced level. This has reduced the rework cost and production cycle.

The conical workpieces of the harvesting bin: Welding problems in complex spaces

The conical workpieces of the harvesting bin need to be welded both internally and externally. Due to the special structure of the conical slopes and the laterally inclined insertion surfaces, it is difficult for manual workers to reach these areas. Moreover, the teaching process of traditional robots is extremely inefficient and lacks precision.

LE Robotics employs multi-modal intelligent perception technology, combining Loyalty AI, 3D vision, and the RX welding process library. It can automatically identify the shape and position of the workpieces, flexibly plan multi-angle welding paths, and achieve efficient welding in complex spaces.

The welding efficiency has been improved, and the operation difficulty has been significantly reduced. It has successfully overcome the high-precision tasks that are difficult for manual workers and traditional robots to complete, providing a standardized solution for the welding of special-shaped workpieces.

——END——

Contact