Traditional steel processing and distribution centers rely on manual labor, resulting in low efficiency and safety hazards. Limited by the construction site, small-scale distribution centers fail to meet the demands of large projects, and the traditional processing methods cannot guarantee the welding quality of the products. Therefore, it is necessary to explore new processing methods to address these issues.

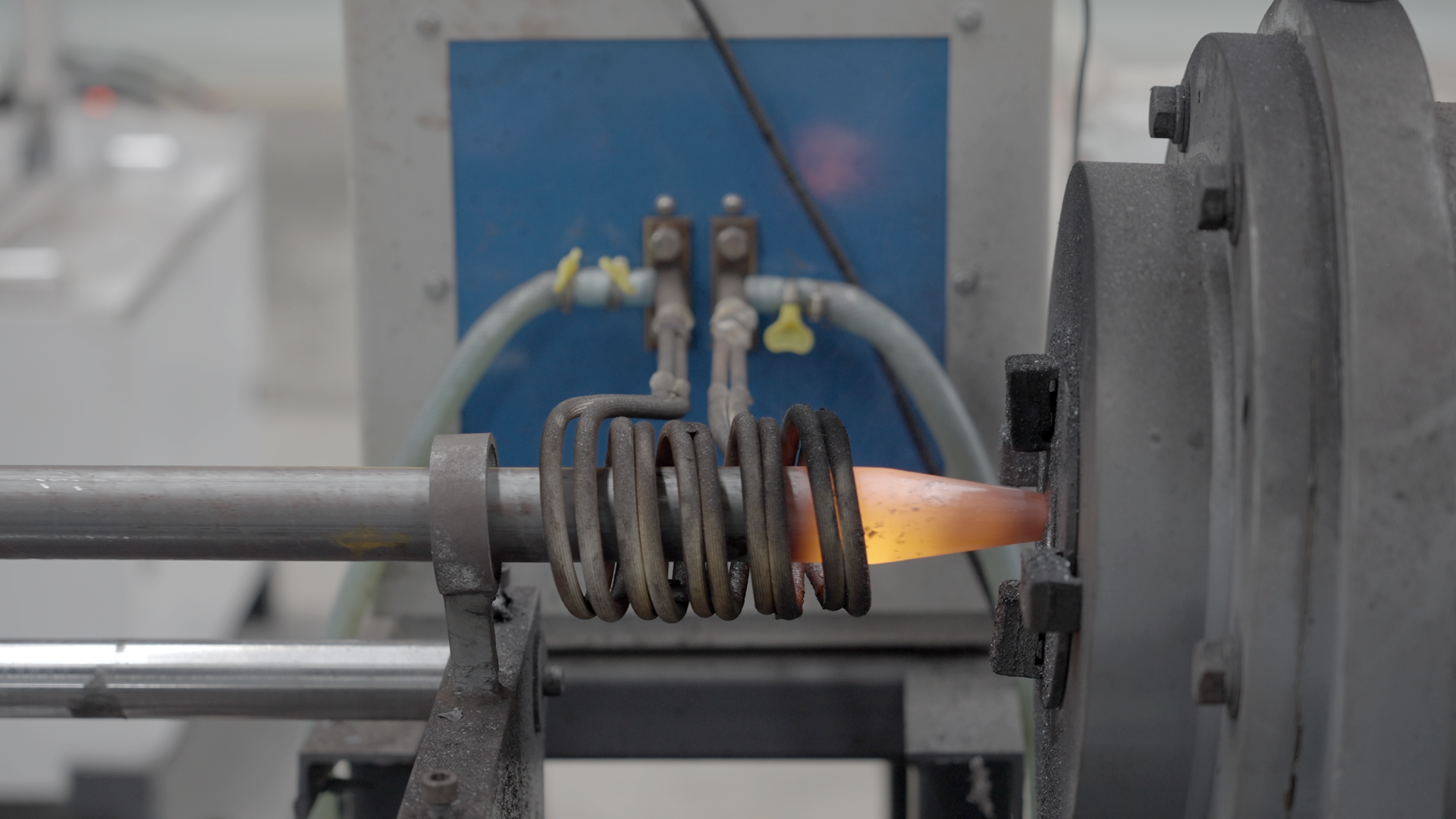

The center adopts LE Robotics Welding Robot's intelligent equipment for an unmanned factory with automation and intelligent devices. This implementation involves robot operations, reducing dependence on manual labor and enhancing production efficiency and product quality. Simultaneously, a customized information management platform facilitates real-time ordering and distribution through mobile phones, meeting on-site production's personalized needs. The operation process incorporates advanced equipment and processes, characterized by automation, informatization, digitization, and intelligence. Robot welding improves welding quality.

After transitioning to automated and intelligent production, the center employs robots for all key processing operations, reducing traditional workforce requirements by 85%. Only seven operators are now required on-site. Efficiency has increased by 81% for small pipe processing, 200% for tunnel mesh processing, and 50% for H-shaped steel arch production, resulting in an overall efficiency doubling. Welding quality has improved by 30%, and cost savings are estimated at 35 million RMB.

Contact