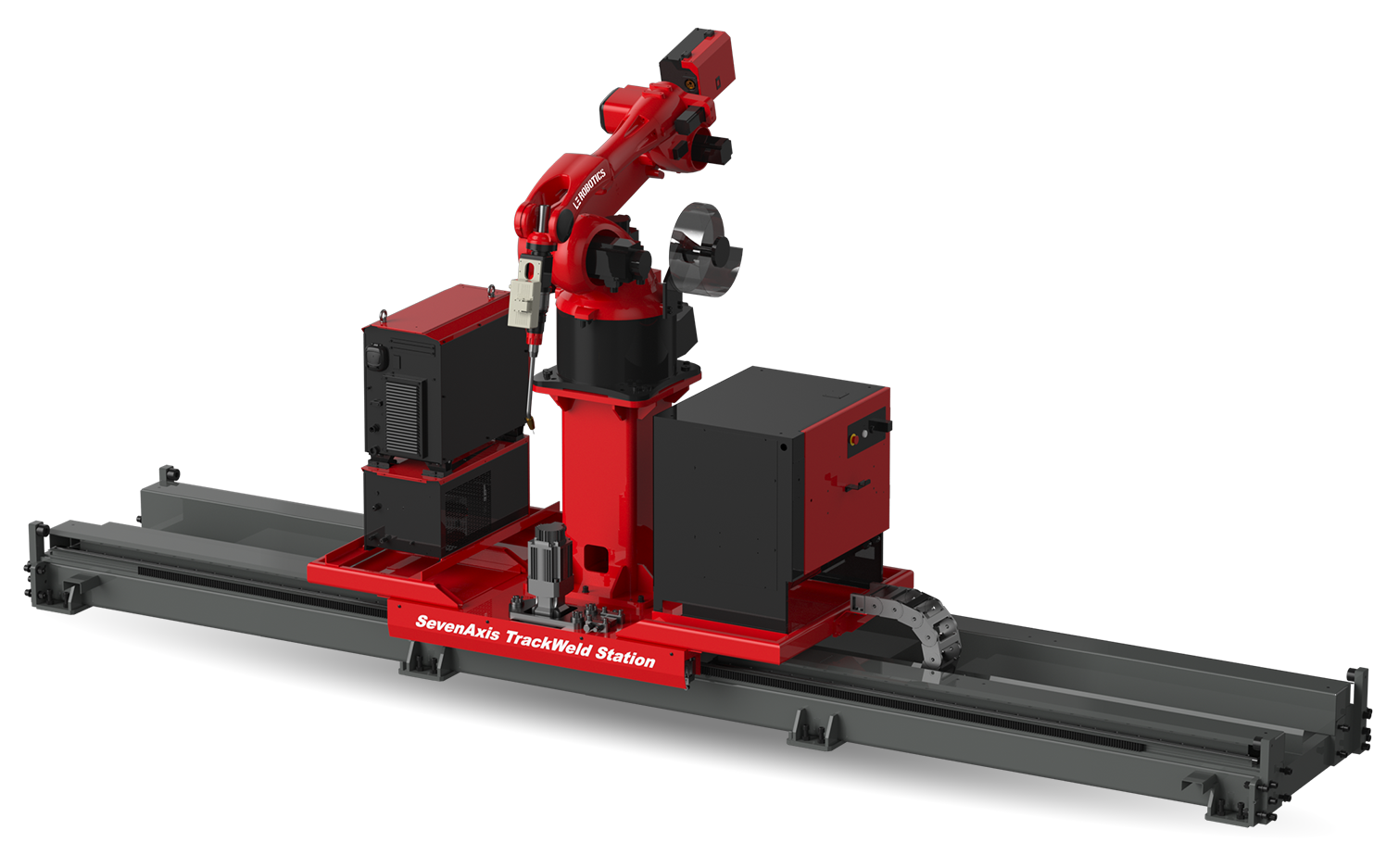

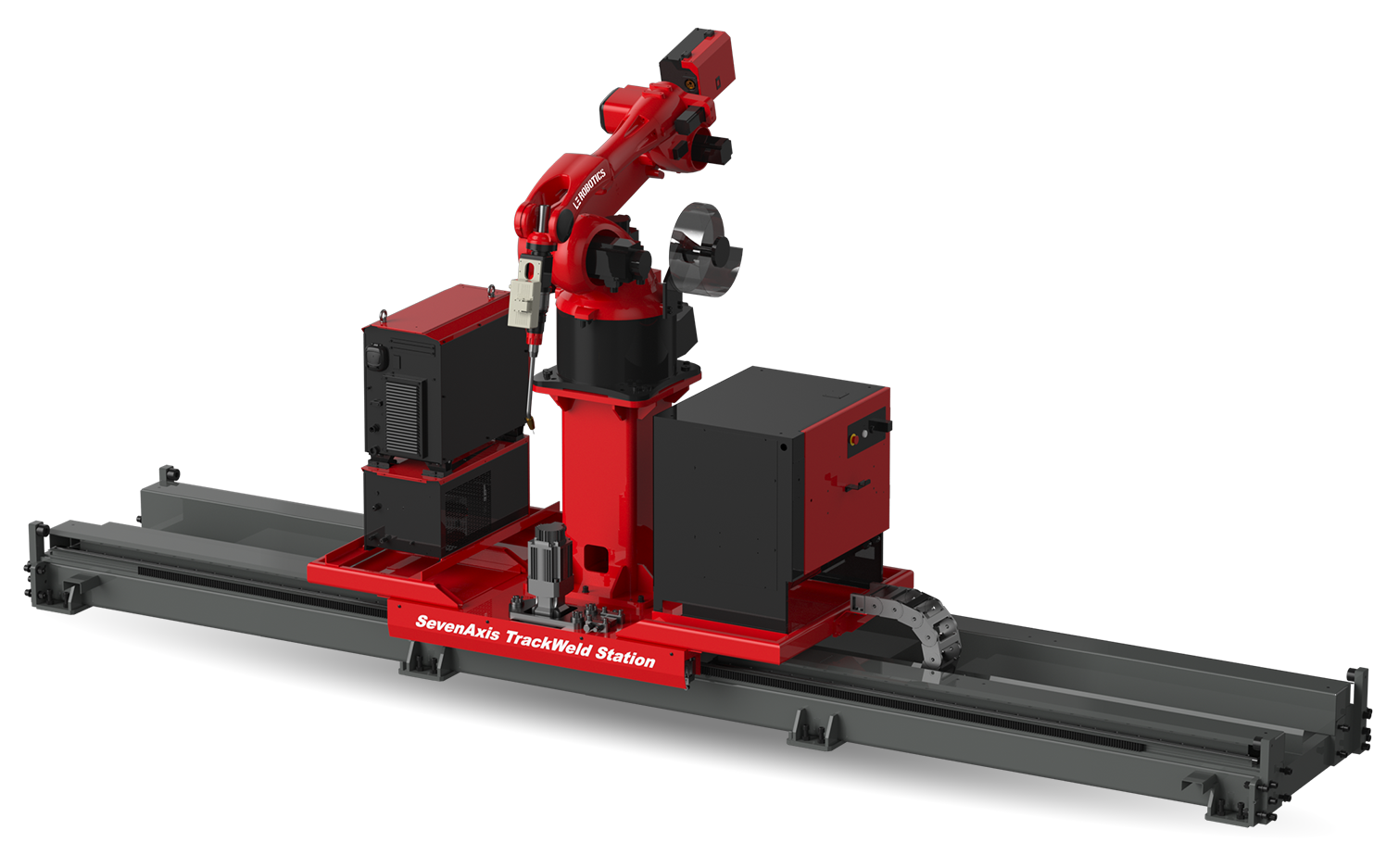

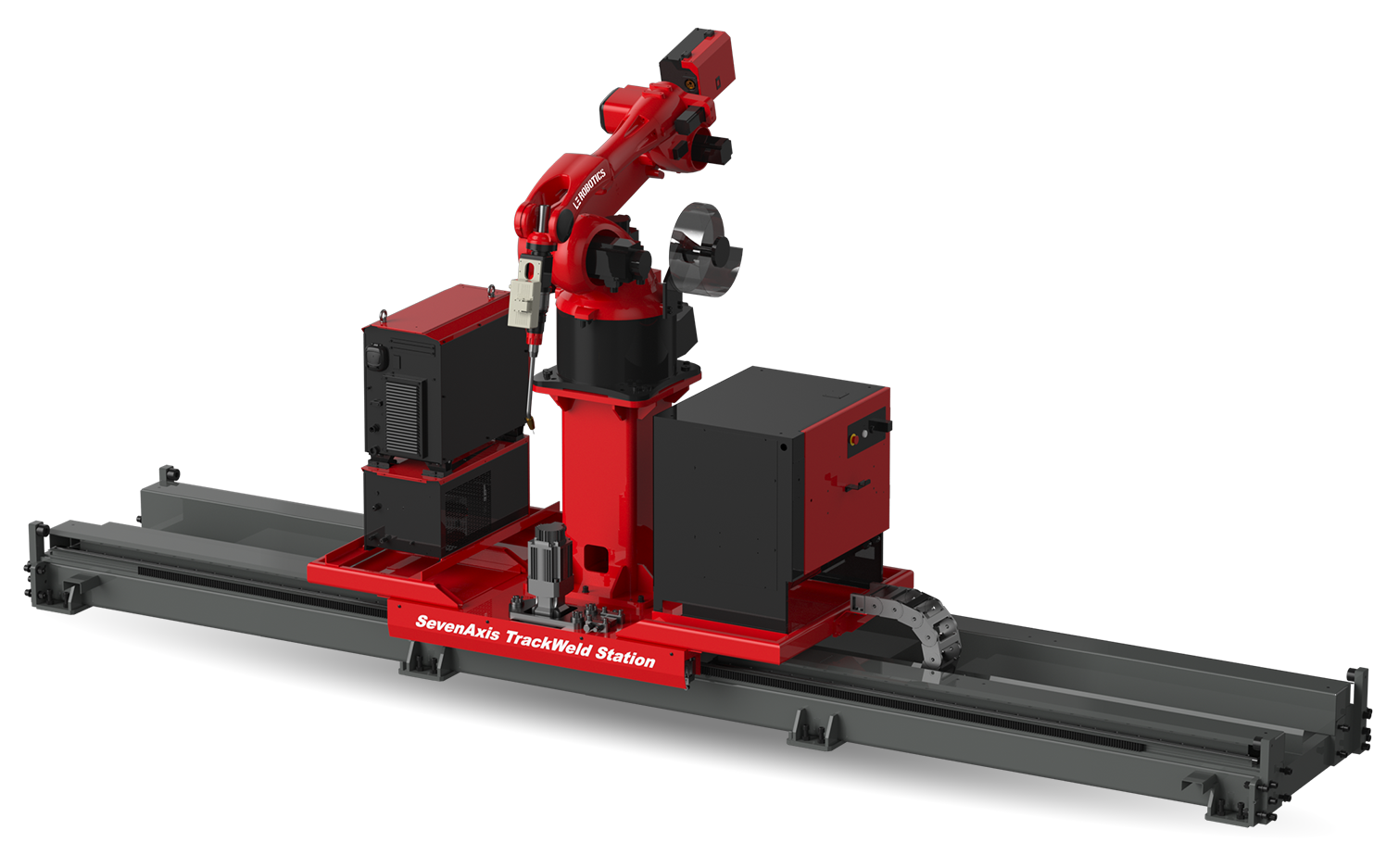

Focusing on welding long and slender workpieces such as H-Beam and box girders. A 7 - axis robot collaborates with the ground rail to expand the working space, and dual workstations can be set on both sides of the rail. Equipped with the Loyalty AI Welding System, it enables programming - free and teaching - free operation, with functions like one - click weld seam extraction, automatic calibration, and intelligent arc tracking. It supports reverse modeling without drawings, 3D drawing import, and digital twin, and can automatically recognize workpieces of common shapes for fully intelligent welding.

Loyalty AI Welding And Cutting System

Loyalty AI Welding And Cutting System

Programming-free and Teaching-free

One-click Weld Seam Extraction

Automatic Calibration

Intelligent Arc Tracking

Reverse Modeling without Drawings

3D Drawing Import

Digital Twin

Automatic Recognition of Common - Shaped Workpieces

Multi - Layer and Multi - Pass Welding Process

Offline Simulation Functionality

RX Welding Process

| Category | Item | Parameter |

Basic Parameters | Degrees of Freedom | 7 Axes |

| Maximum End Load | 12 kg | |

| Robot Arm Reach | R=2010 mm | |

| Ground Rail Length | 6 m/8 m/12 m/14 m/16 m | |

| Ground Rail Movement Speed | ≥20 m/min | |

Vision Performance | Vision Accuracy | ≤0.5 mm |

| Scanning Frame Rate | 2000 Frames/Second | |

Battery Performance | Total Machine Power | 30 kw |

| Power Supply | Three-Phase Five-Wire System 3x380 V±10%/50 Hz | |

Application Environment | Ambient Temperature | 0°℃ to +45°℃ (Operating); -20°℃ to +60°℃ (Transport and Storage) |

| Relative Humidity | ≤90%RH(No Condensation) |

Contact