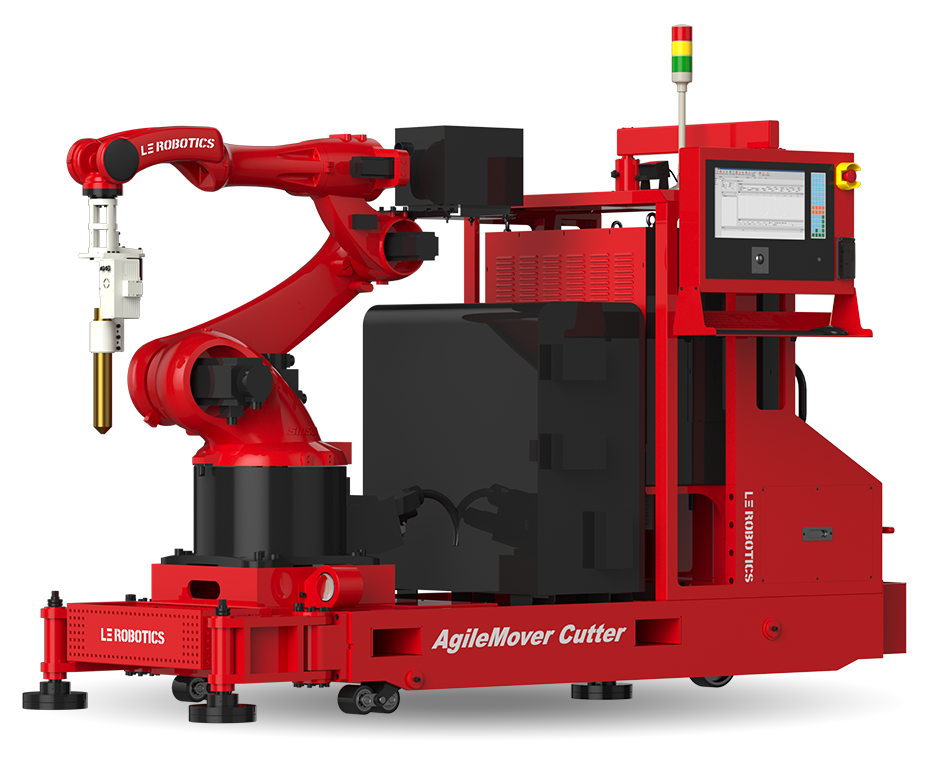

Focusing on narrow-space operations, it features a compact design. Equipped with the Loyalty AI Cutting System and integrated with 3D Vision, it supports visual calibration and deformation compensation. It has functions like bevel editing/nesting and secondary blanking, enabling precise cutting of bent pipes, end caps, branch pipes, conical pipes, and any curved surfaces. With flexible wireless remote control, programming-free and teaching-free operation, and outstanding cost-effectiveness, it helps enterprises reduce costs and improve efficiency.

Loyalty AI Welding And Cutting System

Loyalty AI Welding And Cutting System

Vision Calibration

Deformation Compensation

Groove Editing

Groove Nesting

Secondary Blanking

Bend Pipe Cutting

Head Cutting

Branch Pipe Cutting

Tapered Pipe Cutting

Arbitrary Curved Surface Cutting

RX Cutting Process

| Category | Item | Parameter |

| Basic Parameters | Total Power | 30KVA |

| Operating Power Supply | Three-Phase Five-Wire System 3x380 V±10%/50 Hz | |

| Operating Power Supply Mode | Quick Plug Power Supply | |

| Equipment Weight | 1500 kg(Slight Differences in Selection) | |

| Overall Dimensions (L×W×H) | 2500 mm×900mmx1800 mm | |

| Vision Performance | Vision Accuracy | ≤ 0.5 mm |

| Scanning Frame Rate | 2000 Frames/Second | |

| Standard Vision (Equipped) | RX01 | |

| Battery Performance | Battery Voltage | 48 V |

| Battery Capacity | 32ah | |

| Travel Power Supply | DC48 V | |

| Motion Performance | Robot Arm Reach | 2010 mm(Slight Differences in Selection) |

| Travel Drive | Three-Wheel Drive | |

| Control Method | Wireless Remote Control | |

| Travel Speed | 2.5km/h | |

| Application Environment | Ambient Temperature | 0°℃ to +45°℃ (Operating); -20°℃ to +60°℃ (Transport and Storage) |

| Relative Humidity | ≤90%RH(No Condensation) |

Contact