On March 14th, the 32nd Western Manufacturing Expo and the Eurasian Industrial Expo of 2024 grandly opened at the Xi'an International Convention and Exhibition Center. The LE Robotic Welder (Booth Number: Hall 4, A431) once again became the focus due to its outstanding technical strength and innovative achievements.

At this exhibition, the LE Robotic Welder not only showcased the integration and application of cutting-edge technologies such as artificial intelligence and big data with traditional industrial fields but also, with its profound technical accumulation and rich practical experience in applications, presented to the audience the brand-new welding, cutting, and smart factory solutions for the year 2024. The display highlighted the latest achievements from close cooperation with international industrial giants.

2024 New Product Launch

Technical Innovation Meets the Needs of the Entire Market

(▲New Product Launch Site)

(▲Executive President Hu Haojie Launches New Product)

During the exhibition, Loyalty Robotics Welding Systems (Chengdu) Corporation grandly unveiled the 2024 new robotic welding machines - the IntelliMover Welder, WindRunner Welder, and AgileMover Welder, covering the high, mid, and low-end markets comprehensively to meet the diverse needs of enterprises.

At the new product launch event, Mr. Hu Haojie, the Executive President of LE Robotic Welder, first narrated the original intention behind the product development. He revealed the integration and application of the new product's AI technology with industrial manufacturing, demonstrating how intelligent algorithms and self-learning capabilities can optimize workflows and reduce human errors. He also emphasized the importance of this technology in enhancing process stability and ensuring welding quality, and how real-time data analysis can be used to achieve process optimization, thereby bringing a more efficient and intelligent production experience.

(▲President Xiao Danyang Explains the Advantages of the New Product)

Subsequently, Mr. Xiao Danyang, the President of the company, gave a detailed sharing and demonstration of the new product technology. He particularly highlighted the breakthrough progress in autonomous navigation technology, as well as the efficient application of underlying logic such as no programming and no teaching in actual production. These innovative technologies greatly enhance the autonomy and flexibility of the robots, saving enterprises a significant amount of cost and time.

(▲Director Yin Xianhua Shares Industry Trends)

Additionally, the event specially invited Director Yin Xianhua from the Chengdu Welding Machine Research Institute as a distinguished guest. With his professional perspective and extensive industry experience, Director Yin revealed the future development trends of the industry to the attendees and shared his unique insights into the new type of welding machines. His brilliant speech not only deepened the attendees' understanding of the new products but also provided valuable ideas for the future development of the industry.

Intelligent Production Solutions - Driving Sustainable Development through Technological Innovation

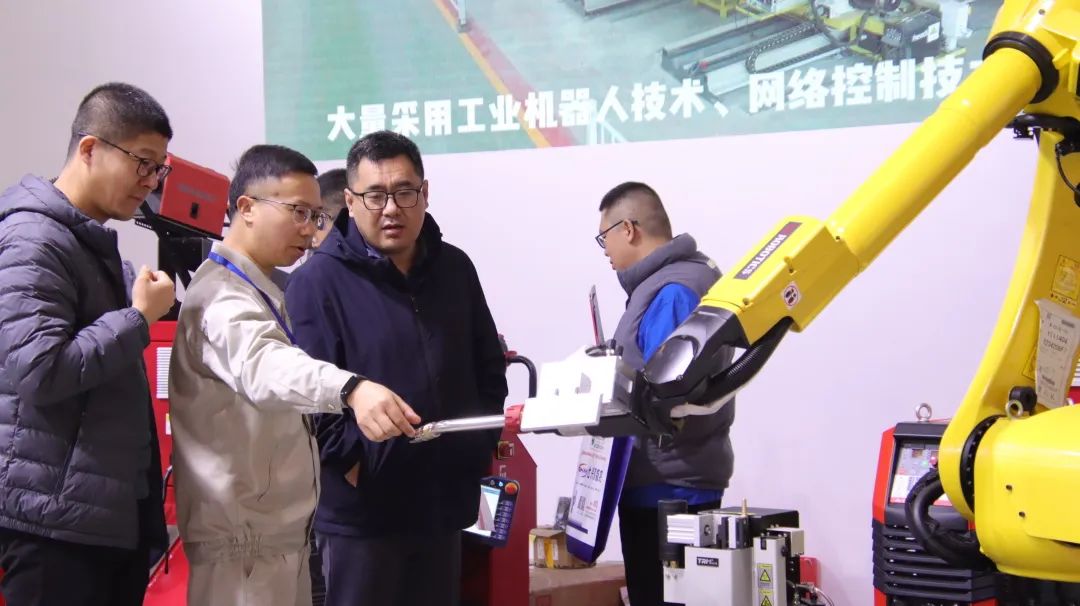

(▲Exhibition Site)

Loyalty Robotics Welding Systems (Chengdu) Corporation is committed to leading technological advancements in the global welding industry. Faced with global challenges, the LE Robotic Welder integrates an advanced remote operating system that combines AI with mobile applications to enhance the flexibility, collaboration, and user-friendliness of intelligent production systems. Even in environments without network connectivity, it can meet users' demands for highly flexible use and ensure the continuity of production activities.

To adapt to various industrial applications, the LE Robotic Welder has increased the level of automation and production efficiency for enterprises by integrating industrial automation plug-ins, optimizing operational parameters, and implementing efficient data management. At the same time, standardizing operations such as handling, cutting, and welding has significantly reduced the cost of technical support.

(▲Exhibition Site)

In the field of automated welding technology, Loyalty Robotics Welding Systems (Chengdu) Corporation continuously innovates to meet the market's demand for intelligent welding solutions. The core technologies of 3D vision and intelligent control have significantly enhanced the precision of welding operations and the ability to adapt to diverse environments. The application of SLAM autonomous navigation technology has increased the robots' mobility in complex scenarios, expanding their influence in both domestic and international markets.

In addition, the LE Robotic Welder has long been focused on developing disruptive welding technologies to improve production efficiency and welding quality, ensuring high precision and consistency of the welds. The real-time monitoring and adjustment capabilities of this technology not only maintain excellent welding performance but also contribute to reducing production costs.

(▲Exhibition Site" or "Trade Show Venue)

Driven by technological innovation, Loyalty Robotics Welding Systems (Chengdu) Corporation continuously breaks through technical barriers to provide global enterprises with simple and efficient automated and intelligent solutions, as well as digital and intelligent services. These solutions can be applied to customized needs across various industries, empowering companies to build digital factories and achieving their own robust global business growth.

Contact