Saying goodbye to the cumbersome operation of software and stepping into the era of one-click welding and cutting, what kind of experience is it?

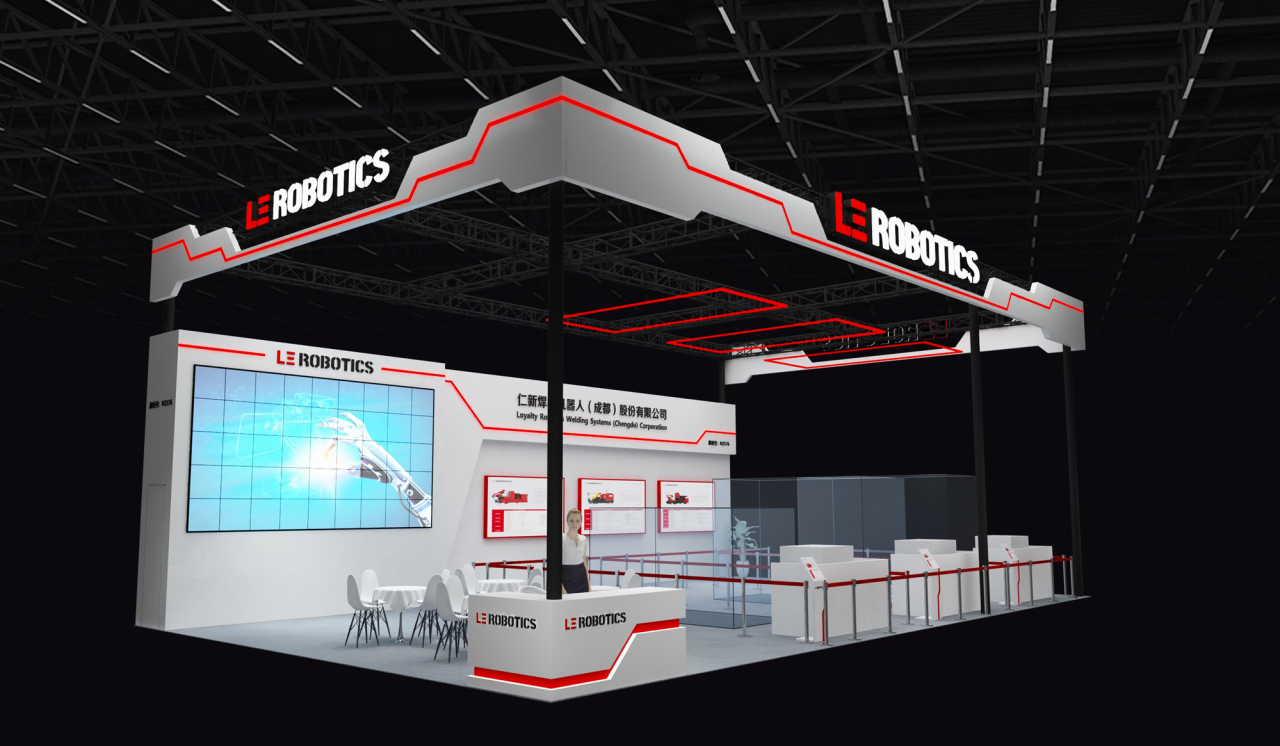

From August 13th to 16th, 2024, the 27th Beijing Essen Welding & Cutting Fair, the most influential welding event globally, will be held at the Shanghai New International Expo Centre.

LE Robotics Welding Machine, as a leading global provider of intelligent manufacturing solutions, will showcase its significant products at this grand event. With core technologies such as 3D vision, SLAM autonomous navigation, and AI artificial intelligence, LE Robotics has successfully broken through the bottlenecks of traditional production.

At this exhibition, LE Robotics will present a comprehensive display of welding and cutting solutions to meet the flexible production needs of small batches and diverse varieties. Additionally, we will conduct several technical demonstrations and sincerely invite old and new friends to visit and exchange ideas.

Time: August 13th - August 16th

Location: Shanghai New International Expo Centre

Position: Hall 3, Booth N3576

Intelligent Welding and Cutting

One-Click Start for Instant Production

1.Navigator Welding

Suitable for structural steel assembly workpieces in fields such as building steel structures, bridge engineering, marine engineering, and large container manufacturing, 3D point cloud processing is used to achieve workpiece recognition and intelligent positioning without the need for programming or teaching. The 3D vision system generates a three-dimensional model, automatically creates welding paths and seams, and matches RX welding process data with robotic welding paths. Fine motion control allows workpieces of any size to be placed freely, and SLAM autonomous navigation technology enables positioning without the need for jigs or fixtures; wherever the workpiece is, the robotic welder will go there.

2.Strider Welding

Suitable for welding steel components in outdoor environments with difficult and complex terrain, the tracked walking system provides stable performance on rugged mountains, muddy roads, and desert areas. AI technology, intelligent algorithms, and autonomous learning enable rapid response in seconds. The RX welding process library, supported by a vast amount of data, offers a myriad of solutions to choose from. 3D vision and three-dimensional scanning ensure precise and flawless welding quality.

3. WindRunner Cutting

Designed for fully automatic flexible cutting of large components made of various metal materials, it supports both oxy-fuel and plasma processing methods, and is equipped with a differential bridge power system and dual-wheel steering function. With 3D vision technology and wireless remote control driving technology, it achieves autonomous cutting path planning without the need for programming or teaching, capable of cutting various spatial curves. The 3D vision automatically generates cutting trajectories and, through global positioning technology, automatically matches cutting parameters without the need for jigs, ensuring cutting quality.

——END——

Contact