SIASUN Robotics Booth

Intelligence Leads, Empowers New Quality Productivity.

In 2024, LE Robotics Welder is breaking new ground, committed to leading future flexible production models with core welding and cutting technologies, striving to be the "main force" in intelligent manufacturing, and becoming an outstanding representative of new productive forces in the field of intelligent welding and cutting. At this exhibition, LE Robotics Welder will join hands with SIASUN Robotics (Booth A239 in Hall 7.1), a powerful collaboration to showcase the most cutting-edge intelligent manufacturing technologies, and invite you to explore new opportunities in intelligent manufacturing together!

01

IntelliMover | Welding:

Equipped with a steering wheel power system, it has the characteristic of omnidirectional movement, which can help customers overcome the pain points of rough terrain. With 3D vision technology, AI technology, and autonomous navigation technology, it eliminates the need for programming or teaching. It comes with the RX welding process library, making welding operations more precise and flexible. The mobile app allows for remote task scheduling and enables collaborative operations among multiple robots, meeting users' dynamic production needs.

03

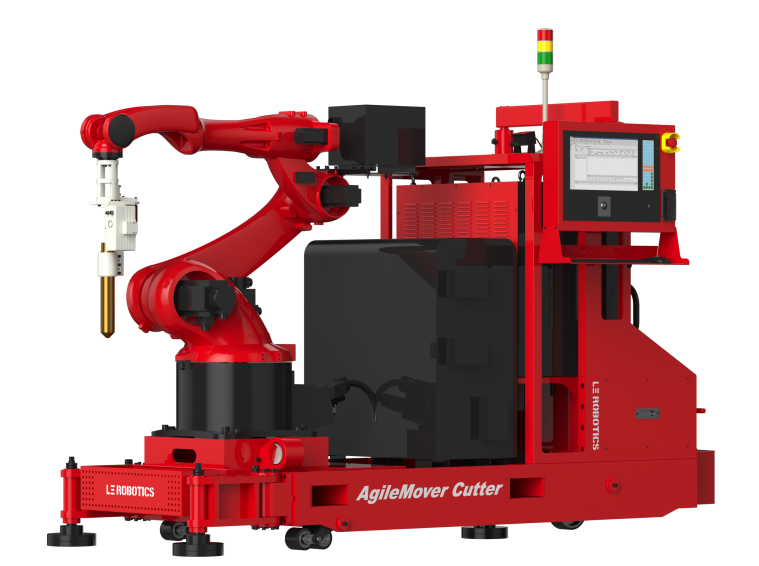

AgileMover | Cutting:

The ultimate cutting tool for confined spaces, with a compact design. The vehicle is equipped with wheel hub motors and a power steering system, offering wireless remote control driving with flexible movement and steering. With 3D vision technology and AI technology, it eliminates the need for programming or teaching, allowing for autonomous planning and determination of cutting paths, capable of achieving various spatial curve cutting trajectories. AgileMover's strong price advantage makes it an ideal choice for enterprises looking to increase production efficiency and reduce labor costs.

LE Robotics Welder Booth

Immersive Cloud Exhibition Experience

On the first day of the Industrial Expo, LE Robotics Welder will join industry experts to discuss industry trends, gain in-depth insights into the development trends in the field of intelligent manufacturing, and unveil its revolutionary applications. LE Robotics Welder will also lead audiences on a virtual tour of its nearly 400-square-meter exhibition hall through a variety of live streaming events, showcasing new product launches and expert interpretations, providing an immersive online exhibition experience.

Scan the QR code to make an appointment and get your exhibition ticket!

——END——

Contact