Introduction

With the rapid advancement of technology and intelligent manufacturing driving industrial transformation, from December 20th to 22nd, 2024, the 2024 World Intelligent Manufacturing Expo grandly opened at the Nanjing International Expo Center, bringing together global cutting-edge intelligent manufacturing technologies and innovative achievements.

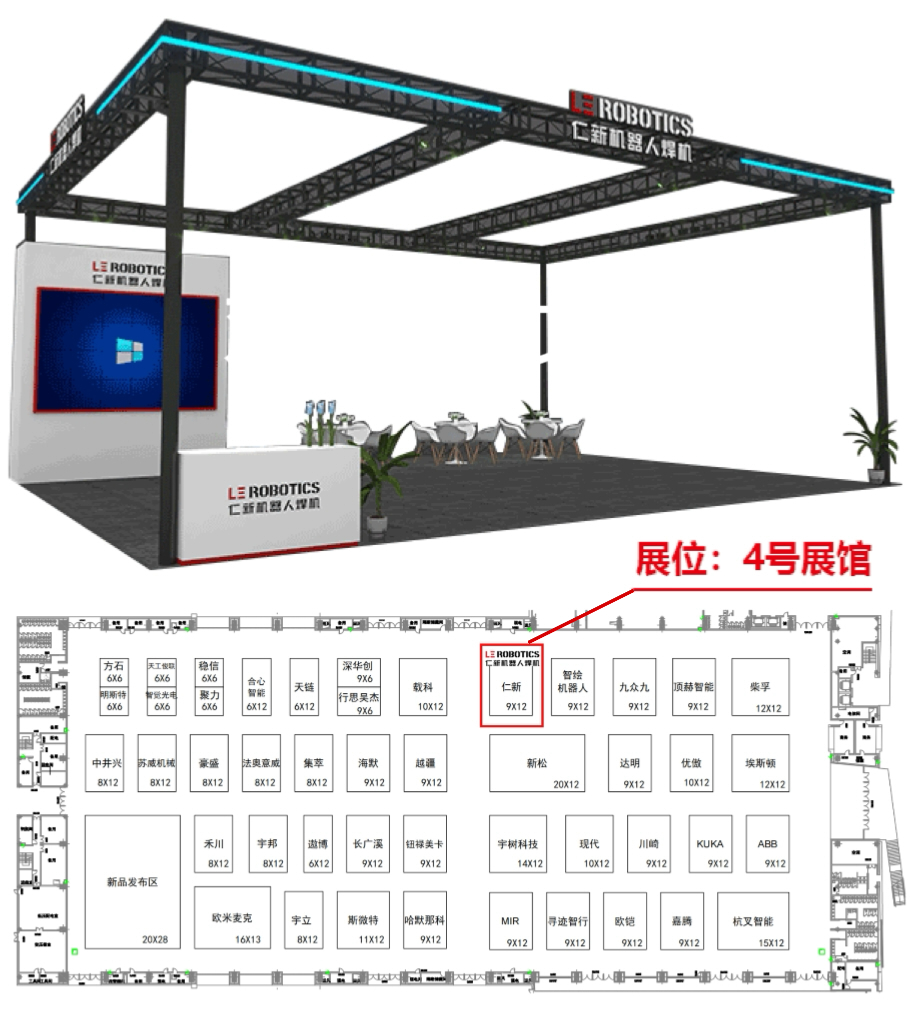

As a leading enterprise in the field of AI welding and cutting, LE Robotics made a grand appearance with its "application-oriented humanoid robot" that breaks through industry bottlenecks, achieving a deep integration of AI and industry. At this exhibition, LE Robotics entered Hall 4 with the theme of "AI Empowers Welding and Cutting, LE Robotics Creates and Leads the Future", making a joint appearance with the four major families of robots, and centrally displaying heavyweight products and cutting-edge technologies, fully demonstrating the innovative and application achievements of intelligent manufacturing.

1

The achievements of LE AI and the "application-oriented humanoid robot" are on display.

The exhibition area for the in-depth application display of LE AI and its core technologies will comprehensively and immersively showcase the innovative application achievements of LE AI. Relying on the coordinated operation mechanism of "hands, feet, eyes, and brain", it ingeniously incorporates innovative humanoid robot elements to visualize cutting-edge technologies.

Eyes: The high-precision 3D vision system equipped with advanced sensors can capture the weld seam path or cutting contour with ultra-high millimeter-level accuracy under complex lighting and workpiece surface conditions, and quickly transmit the data back to the "brain".

Brain: Using intelligent algorithms trained with massive data, it can quickly analyze the material and process requirements of different workpieces and make accurate decisions instantly to match the most suitable welding or cutting parameters.

Hands: Namely, the flexible and stable robotic arm that precisely executes operations according to instructions, with smooth movements and accurate positioning.

Feet: The SLAM autonomous navigation technology allows it to move flexibly along the planned path within the workplace, seamlessly connect with surrounding equipment, and achieve efficient collaborative interaction.

2

IntelliMover | Welder: The "Miracle Tool" for Welding in Multiple Scenarios

The IntelliMover robotic welder integrates AI, 3D vision, SLAM autonomous navigation, and the RX welding process library, and is suitable for welding complex workpieces such as large and heavy equipment, energy and power facilities, and shipbuilding components.

For complex workpieces in multiple industries such as machinery manufacturing, building steel structures, and environmental protection equipment, LE's AI intelligent welding technology optimizes parameters in real time through machine learning, and ensures stable and reliable welding quality and strict compliance with process standards by accurately controlling key indicators such as welding requirements.

The 3D vision system can accurately identify the position of the weld seam, and can skillfully adapt to complex structures such as irregular shapes and curved surfaces with the functions of no programming and no teaching, greatly shortening the preparation time before welding. The SLAM autonomous navigation technology enables the robotic welder to move autonomously in the workshop, flexibly shuttling between different workstations and production lines, and calmly coping with various production scenarios such as mass production and small-batch customization.

3

WindRunner | Cutter: Speed and Precision, Solving the Dilemma of Complex Cutting

The WindRunner robotic cutter, combined with LE AI and 3D vision technology, is widely used in complex cutting tasks with its high-speed and high-precision cutting capabilities.

In the field of head cutting, the WindRunner robotic cutter achieves a smooth cutting surface and high dimensional accuracy with its advanced technology and precise control, significantly improving production efficiency and reducing subsequent processing steps. It is suitable for fields such as heavy machinery manufacturing and petrochemical equipment.

In the circumferential cutting of the groove of the girder workpiece, the cutting parameters are intelligently adjusted to ensure the accuracy of the groove angle and size, providing a reliable foundation for subsequent welding and enhancing the structural safety.

Empowered by LE AI and 3D vision technology, the WindRunner robotic cutter, with its excellent technology, precise control, and intelligent adaptability, has opened up complex cutting links in multiple industries such as heavy machinery, petrochemicals, construction, and bridges, and has truly become a key weapon to help manufacturing upgrades and cost reduction and efficiency improvement in various fields.

4

Experience intelligent manufacturing and win nice gifts.

During the exhibition, visitors are welcome to visit the booth of LE Robotics. By participating in the on-site activities, they will have the opportunity to receive exquisite gifts and take away full surprises while experiencing the charm of intelligent manufacturing.

码上预约,领取免费观展门票

——END——

Contact