LE Robotics × Xingqing

AviationCross-Border Collaboration to Expand New Horizons of New-Quality Productivity!

On December 3rd, Zheng Zhong, Chairman of Sichuan Xingqing Aviation, and Yu Cheng, CEO, led a delegation to visit LE Robotics, accompanied by Xiang Yujie, General Manager of Southwest China at Guojin Securities. Hu Haojie, CEO of LE Robotics, together with the core team, received the delegation. Both parties conducted in-depth exchanges on the innovation, cross-border integration and scenario implementation of industrial embodied intelligence technology, reached strategic cooperation consensus and officially signed the agreement.

During the exchange, Hu Haojie focused on introducing the self-developed full-stack "Hand-Eye-Foot-Brain" collaborative technology system: with AI as the core and integrated with the concept of industrial embodied intelligence, it has achieved stable application in high-end manufacturing fields such as rail transit and energy equipment, representing a concrete practice of new-quality productivity in industrial scenarios.

Combined with its own experience, Xingqing Aviation put forward the application concept of this technology in UAV platforms and aerial operation scenarios. Both parties agreed that the cross-border integration of core technologies can not only solve the automation problems of complex ground processes, but also is expected to promote "aerial robots" to achieve high-precision operations, expand new scenarios for high-end manufacturing, and further release the value of new-quality productivity.

Both parties stated that starting from this signing, they will build a reusable collaborative path around "engineering technology + intelligent manufacturing + platform capabilities": LE Robotics will continue to accumulate core technical capabilities under complex working conditions relying on the AI-driven "perception-decision-execution" closed loop; Xingqing Aviation will give play to its advantages in aviation manufacturing and aerial platforms to provide high-value application scenarios and high-standard verification environments. In the future, the two parties will deepen cooperation through verifiable, deliverable and replicable joint projects, accelerate the industrialization of technologies, and expand the boundaries of new-quality productivity.

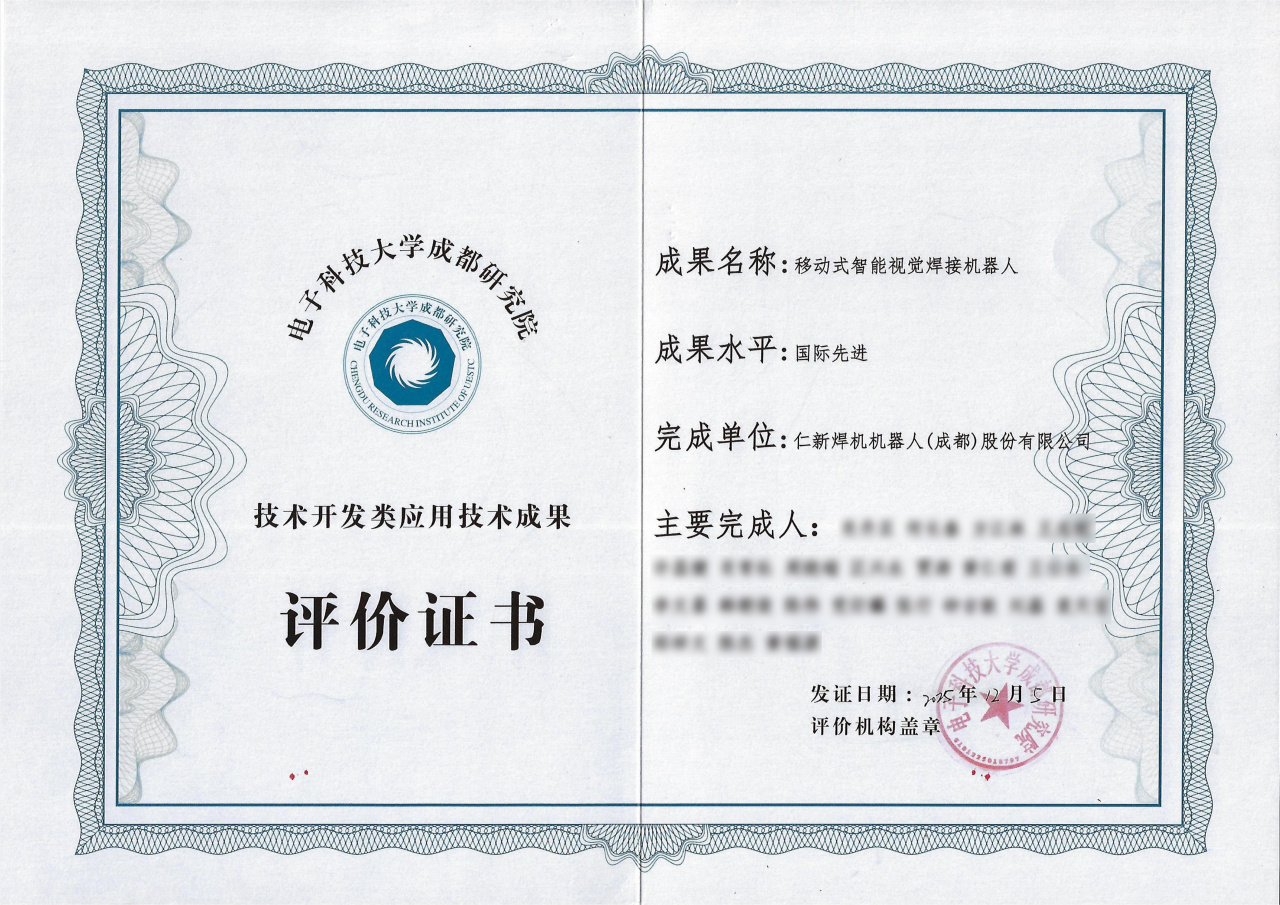

LE Robotics' Mobile Intelligent Vision Welding RobotRated Internationally Advanced

Recently, the "Mobile Intelligent Vision Welding Robot" independently developed by LE Robotics was rated at the "internationally advanced" level following a technical achievement evaluation organized by the Chengdu Research Institute of the University of Electronic Science and Technology of China. This evaluation result not only serves as authoritative recognition of LE Robotics' core capabilities in intelligent welding, but also provides a "implementable, replicable, and rapidly effective" intelligent upgrading path for a broader range of manufacturing enterprises.

In the current manufacturing industry, small and medium-sized enterprises (SMEs) and those in niche sectors generally face challenges in implementing welding intelligence: small-batch, multi-variety production has become the norm, while traditional fixed welding equipment is complex to retool and lacks flexibility; meanwhile, some high-end intelligent welding equipment features high operational thresholds and limited scenario adaptability, hindering their widespread application.

Addressing these pain points, and centering on the real needs of SMEs—such as "small-batch, multi-variety, and frequent retooling"—LE Robotics has completed product design and capability integration with engineering applicability as the top priority:

Stable recognition under complex working conditions: The 3D vision system can stably identify weld seams amid spatter, strong light, and other harsh conditions, reducing the strict requirements for environmental consistency and workpiece uniformity.

Programming-free rapid operation: Reduces reliance on high-threshold engineering debugging in traditional automation, ensuring "efficiency improvement" does not come at the cost of "deployment cycles".

Mobile structure and lightweight interaction: Adapts to narrow workshops and temporary operation points; ordinary technicians can master the operation after short-term training, truly lowering the threshold for large-scale adoption of intelligent welding.

Next, the company will establish a more systematic pilot mechanism to collaborate with customers in niche sectors, advancing "scenario-based verification—parameter solidification—solution standardization—delivery replication", bringing "internationally advanced" technology to more manufacturing scenarios.

LE Robotics Shines at 2025 GGII Robotics Annual ConferenceClaims Annual Technology Award!

From December 15th to 17th, the 2025 (12th) GGII Robotics Annual Conference & Golden Ball Awards Ceremony was held in Shenzhen. As a representative enterprise in the field of industrial embodied intelligent welding and cutting, LE Robotics was invited to attend. Hu Haojie, CEO of LE Robotics, participated in the peak leadership dialogue and won the "Annual Technology Award" at the GGII Golden Ball Awards for his continuous innovation and engineering practice in intelligent welding.

This year's annual conference gathered leading enterprises, scientific research institutions and industry experts in the global robotics industry, focusing on core topics such as embodied intelligence and the application of industrial robots. In the peak dialogue themed "Resilient Growth and Emerging Prosperity of Industrial Robot Enterprises", Hu Haojie shared LE Robotics' technical practices and development insights around the entry path, business model and segment track selection of embodied intelligence.

Hu Haojie said that LE Robotics has always been guided by industrial needs, deeply engaged in the industrial embodied intelligence track, and built a full-stack self-developed "perception-decision-execution" closed-loop system. The company's independently developed core technologies have reached the international advanced level, effectively solving industry pain points such as difficulty in recruiting welders, low efficiency and unstable precision in traditional welding. Adhering to the equal emphasis on technological innovation and scenario implementation, the company transforms welders' experience into iterable intelligent algorithms, providing highly adaptable intelligent welding and cutting solutions for industries such as petrochemical equipment, rail transit and shipbuilding, and reducing industry transformation costs through ecological collaboration.

On December 17th, at the GGII Golden Ball Awards Ceremony, LE Robotics was awarded the "Annual Technology Award" in recognition of its technological breakthroughs in the field of industrial embodied intelligence, large-scale engineering application capabilities, and practical contributions to the intelligent upgrading of the industry. This fully demonstrates the industrialization value of the company's core technologies and its strength in engineering implementation.

The award not only affirms LE Robotics' phased achievements but also further confirms the forward-looking nature and sustainability of its long-term development path. In the future, LE Robotics will continue to be driven by industrial needs, promote the standardization of technologies and the large-scale implementation of solutions, upgrade from "project delivery" to "platform capability output" through ecological collaboration, and continuously empower the development of high-end manufacturing towards intelligence and high-endization.

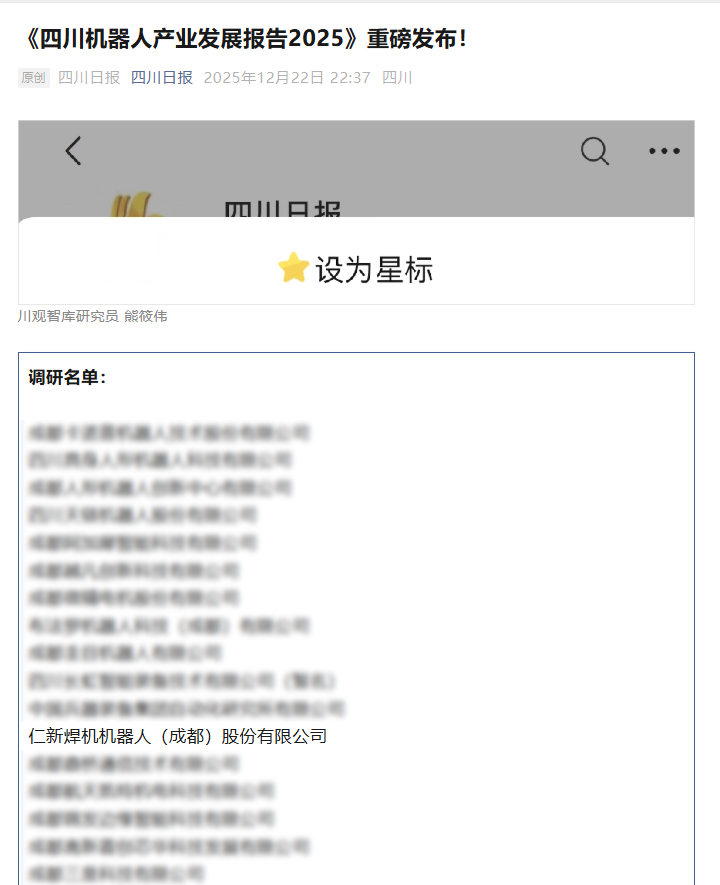

2025 Sichuan Robotics Industry Development Report Grandly ReleasedLE Robotics, a Benchmark Sichuan Enterprise, Invited for an Interview

Recently, the 2025 Sichuan Robotics Industry Development Report, officially released by Sichuan Daily's official platform, made its debut. As an in-depth industrial report launched by a provincial authoritative media outlet, it systematically sorts out the development pattern, core advantages, and upgrading direction of Sichuan's robotics industry, boasting high industry guiding value and credibility. As a representative enterprise in Sichuan's industrial embodied intelligence field, LE Robotics was invited to participate in the research and exclusive interview, with its technological innovation and industrialization practices included as a typical case in the report.

Rooted in Sichuan's high-end manufacturing sector, LE Robotics takes the self-developed full-stack "Hand-Eye-Foot-Brain" industrial embodied intelligence technology system as its core, continuously advancing technological R&D and engineering implementation. Currently, the company's products have been applied in multiple key manufacturing scenarios in Sichuan, effectively solving automation challenges under non-standard and complex working conditions.

Leveraging Sichuan Daily's authoritative communication power, the report presents LE Robotics' practices as a representative sample of "Sichuan enterprises' technological breakthrough + local industrial collaboration": Based on Sichuan's industrial foundations such as aerospace and energy equipment, the enterprise has achieved precise alignment between core technologies and local manufacturing needs, expanded application scenarios through cross-industry collaboration, and provided a new path for the development of Sichuan's robotics industry.

Being selected as a typical case in Sichuan Daily's official industrial report is recognition of LE Robotics' technological strength and industrial value, and also highlights its representative role in Sichuan's robotics industry ecosystem. LE Robotics will continue to release the value of new-quality productivity and inject long-term momentum into industrial upgrading.

Hu Haojie

Executive President (CEO) of LE Robotics

Standing at the new stage of accelerated implementation of embodied intelligence, LE Robotics will take the four key breakthroughs in December as a starting point, and continue to advance along the main line of "full-stack self-developed base capabilities — industrial process accumulation — standardized product portfolio — large-scale replicated delivery": Internally, it will continuously strengthen the "Hand-Eye-Foot-Brain" closed-loop capabilities and engineering reliability; externally, it will take strategic partners such as Xingqing Aviation as fulcrums to promote cross-border scenarios from concepts to deliverable results; at the industrial level, through more frequent and high-quality demonstration projects and large-scale delivery, it will drive "Made in China" to achieve sustainable and replicable intelligent upgrading in high-end manufacturing scenarios.

——END——

Contact