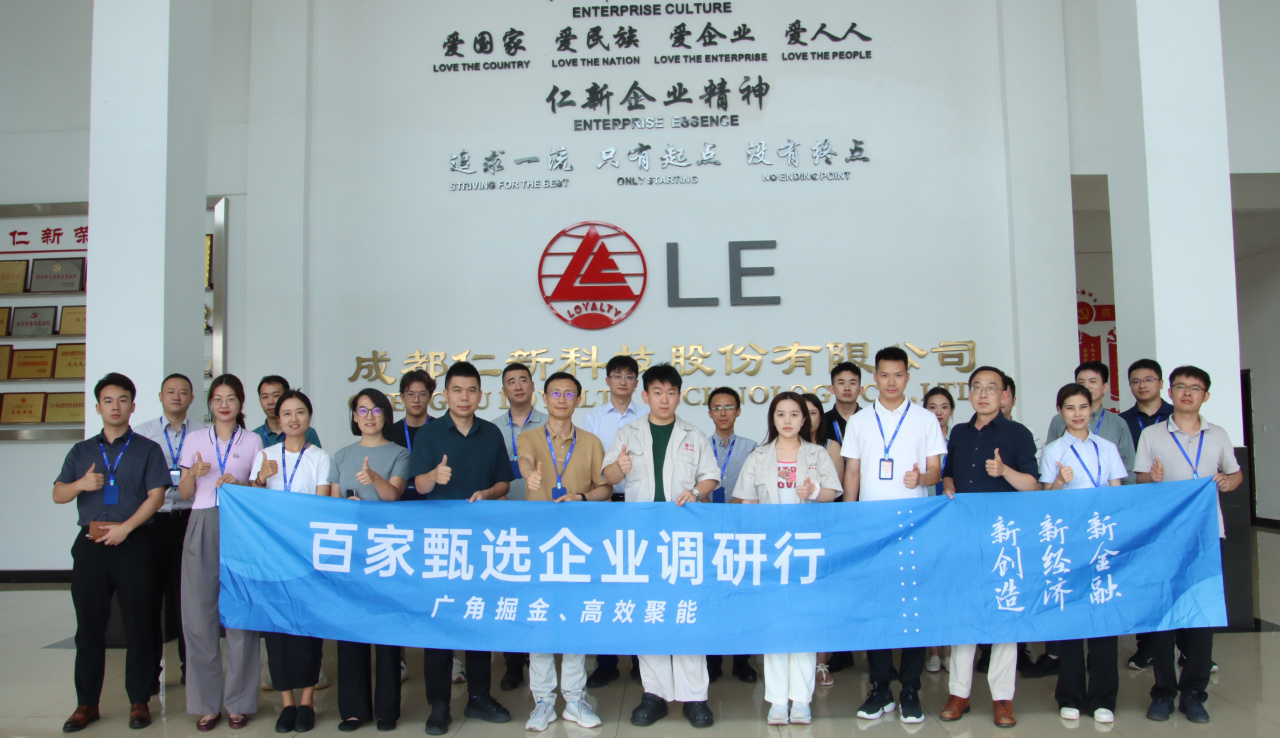

On August 21, 2024, the Sichuan Province Investment Fund Industry Association, along with the project team, visited the 22nd target enterprise - Loyalty Robotics Welding Systems (Chengdu) Corporation (hereinafter referred to as "LE Robotics" or "the Company") for research.

1

Company Visit

On the day of the research visit, Mr. Hu Haojie, the Executive President of LE Robotics, and Ms. Dong Tingting, the Secretary of the Board, led the research team on a tour of LE Robotics' production facilities and provided a detailed introduction to the company's development plans and strategic outlook. LE Robotics, a subsidiary of the Loyalty Enterprises Group, is a high-tech enterprise focused on technological innovation in welding and cutting, committed to providing advanced automation and intelligent solutions for traditional manufacturing industries.

At the factory site, Mr. Xiao Danya, the company's president, introduced to the research team the company's four major product series: robotic welding machines, robotic cutting, intelligent robotic welding stations, and intelligent robotic factory solutions. The core technologies cover the forefront of today's technology, including 3D vision technology, artificial intelligence (AI), SLAM autonomous navigation, and robotic control technology.

2

Corporate Dialogue

A. Company Products

After the factory tour, according to Mr. Hu, the company has differentiated its market positioning by choosing intelligent solutions for non-standard welding as its direction, and has set the goal of "Trust LE Robotics for welding and cutting, any need is worry-free." The welding robots developed and produced by the company have competitive advantages in the industry.

Currently, the company's products are widely applied in a variety of production scenarios such as large-scale engineering machinery, construction machinery, wind power equipment, petroleum equipment, environmental protection machinery, machinery manufacturing, shipbuilding, and automotive manufacturing, capable of meeting the strict requirements of different materials and processes.

The company's partners include several state-owned enterprises, central enterprises, and Global Top 500 companies, including well-known domestic enterprises like China Railway Group, PetroChina, CRRC, and Shudao Group, as well as numerous internationally renowned multinational companies from Southeast Asia, Central Asia, North America, and South America. In particular, in cooperation with Shudao Group, our automatic welding system has significantly improved production efficiency and product quality by 50%, reduced labor costs and production cycles, creating significant economic benefits for our clients.

The company focuses on both domestic and international markets, aiming to become a global leader in the field of welding and cutting. In cooperation with Global Top 500 companies, the company's solutions have helped them achieve standardization and intelligentization of production processes globally, meeting world-class manufacturing standards. Through cooperation with internationally renowned enterprises, the company has entered key markets such as North America, Europe, and Southeast Asia, and has established a global network of technical services and sales to meet the diverse needs of customers.

The research team also learned that, in addition to large clients and well-known enterprises, LE Robotics also provides customized solutions for small and medium-sized enterprises, helping them achieve intelligent manufacturing transformation.

B. Technical Advantages

How to maintain technological leadership in the field of non-standard welding? According to Mr. Hu, LE Robotics has facilitated the transition of traditional manufacturing to intelligent manufacturing through comprehensive automation solutions. These technological breakthroughs have not only addressed multiple pain points within the industry but also provided significant support for the development of intelligent manufacturing, helping to enhance the country's competitiveness in the global field of intelligent manufacturing.

The technological innovation of LE Robotics Welding Machines and Intelligent Factory Solutions is mainly reflected in the following aspects:

High-precision welding technology, by utilizing advanced sensors and real-time monitoring systems, significantly enhances the accuracy and consistency of welding, effectively overcoming the issue of low precision associated with traditional welding techniques.

The AI self-learning function enables the welding machine to autonomously learn and optimize welding parameters through artificial intelligence algorithms, adapting to different materials and conditions, thereby solving the problem of operational instability brought about by reliance on human experience.

Intelligent factory solutions integrate technology using the Internet of Things (IoT) to achieve seamless integration between equipment, production data, and management systems. Through real-time monitoring, predictive maintenance, and optimization of production processes, downtime and production costs are significantly reduced. The implementation of smart factories optimizes resource allocation, thereby reducing waste and costs.

Human-robot collaboration technology promotes the collaborative work between humans and machines, not only improving safety and efficiency but also overcoming the limitations of relying solely on automation or manual operations.

C. Key Users (including product structure) and Differentiated Competitive Advantages

Regarding the core strengths of the company, which is also the focus of this research and discussion, LE Robotics' welding products are widely applied in various fields, including automotive manufacturing, construction machinery, heavy industry, and shipbuilding. The competitive advantages of the company are mainly reflected in the following aspects:

Technological Innovation Advantage: The company has a strong R&D team composed of top domestic and international universities and research institutions, continuously conducting technological innovations. Our products are in a leading position in the industry in terms of welding precision, speed, and stability.

Localization Service Advantage: Compared with international brands, the company has a clear advantage in service response speed and localization customization, being able to quickly adjust product design and parameters according to customer needs, providing solutions that better meet user requirements.

Comprehensive Solutions: The company not only provides high-quality hardware products but also offers customers integrated intelligent manufacturing solutions, supporting from the initial design to the later maintenance, helping customers achieve a comprehensive upgrade of their production lines to full automation and intelligence.

Cost-Performance Advantage: The company focuses on cost control, providing competitive prices while ensuring high performance, allowing more enterprises to enjoy the benefits brought by intelligent manufacturing.

On the one hand, with the advancement of national intelligent manufacturing and the integration of 5G, AI, and big data with the manufacturing industry, the level of intelligence and automation of welding robots will be enhanced, bringing new opportunities. On the other hand, the rise in labor costs and the increased demands for production efficiency and quality mean that the company's solutions for non-standard welding processes and intelligent manufacturing have effectively helped customers reduce costs and increase efficiency. As the upgrade of manufacturing automation promotes the widespread application of welding robots in the automotive, construction machinery, and shipbuilding industries, it is expected that the global market will maintain a double-digit average annual growth, reaching a trillion-scale size.

Faced with international competition, Loyalty Robotics has competitive advantages through technological innovation and quality improvement, possessing core technologies and R&D teams. Industry challenges include technological barriers, dependence on imported core components, and the need to improve the after-sales service system. The high initial investment cost for small and medium-sized enterprises is also a concern. With the enhancement of domestic technology and policy support, the performance-price advantage of domestic welding robots becomes apparent, and Loyalty Robotics is expected to achieve domestic substitution and increase market share.

D. Business Objectives and Medium to Long-Term Strategy

Regarding the company's future strategic development, Mr. Hu expressed during the exchange that the company's main business objective is to consolidate and enhance Loyalty Robotics' leading position in the field of intelligent welding robots and actively explore domestic and international markets. To achieve this goal, the company has formulated the following medium and long-term strategies:

Firstly, the company will continue to increase R&D investment to promote upgrades in the intelligence, precision, and stability of welding robots and supporting systems. At the same time, the company plans to use artificial intelligence technology to develop more intelligent and efficient welding solutions.

Secondly, the company will comprehensively advance international development based on its existing domestic market. By cooperating with top international companies, the brand's global market recognition and influence will be enhanced. The company also plans to establish R&D centers and service outlets in Europe, America, and the Asia-Pacific region to provide more localized services.

Thirdly, in addition to focusing on traditional fields such as automotive manufacturing and construction machinery, the company will actively expand into emerging application scenarios, such as new energy vehicles, aerospace, and marine engineering, to meet the intelligent manufacturing needs of different industries.

In terms of the application of artificial intelligence, the company places special emphasis on its application in the field of welding robots. One of the important goals for the future launch is the "humanoid robot welder." This robot can perceive the working environment in real-time through visual recognition and deep learning technology and autonomously adjust welding parameters to achieve true "InstantSeam Welding."

These are also the core strengths of the company, which Mr. Hu summarized as: the company's advantages are concentrated in core technology, international layout resources, and an excellent team of talents, and these factors together support the company's continuous development and leading position.

E.Development Plan (Financing, Use of Funds, etc.)

The company plans to complete a new round of financing within the next 12 months to raise 60 million RMB in funds. Financing methods include introducing strategic investors, issuing new shares, and seeking support from government special funds. This round of financing will accelerate the company's development and enhance its capital strength.

The raised funds will mainly be used in the following four key areas:

Technology R&D: Funds will be used to enhance R&D capabilities, especially in cutting-edge technology areas such as artificial intelligence, machine learning, and high-precision sensors. We plan to establish a dedicated technology R&D center and attract top global talent.

Capacity Expansion: Funds will be used to increase production lines, enhance production capacity, upgrade existing production bases, and purchase advanced production equipment to improve production efficiency and product quality.

Market Expansion: Funds will be used to explore new international markets, establish overseas branches and offices, strengthen the global sales network, and increase investment in market promotion and brand building.

Talent Cultivation: Funds will be used to increase investment in employee training and development programs, attract outstanding talent, especially in the areas of technology R&D and international market development.

The company will continue to strengthen technological innovation and product upgrades, enhance cooperation with global advanced enterprises, strengthen the digital after-sales service system to optimize customer experience, and promote green and environmentally friendly sustainable development. Through a scientific financing plan and reasonable capital allocation, the company aims to further consolidate its leading position in the field of intelligent manufacturing and achieve leapfrog development.

Article Source: Sichuan Province Investment Fund Industry Association

——END——

Contact