Introduction

In the tide of globalization, China's manufacturing industry is moving towards the world at an unprecedented speed and scale. Loyalty Robotics Welding Systems (Chengdu) Corporation, as an outstanding representative of China's intelligent manufacturing, with its leading technology and innovative strength in the fields of robotic welding machines, robotic cutting, intelligent robotic welding stations, and intelligent robotic factory solutions, is actively responding to the call to "go global" and has opened a new chapter in its globalization strategy. Its foresight and enterprising spirit not only promote its own international development but also set a benchmark for innovation and efficiency for the entire industry.

Global Innovative Technology: WeldOnMove and InstantSeam Welding

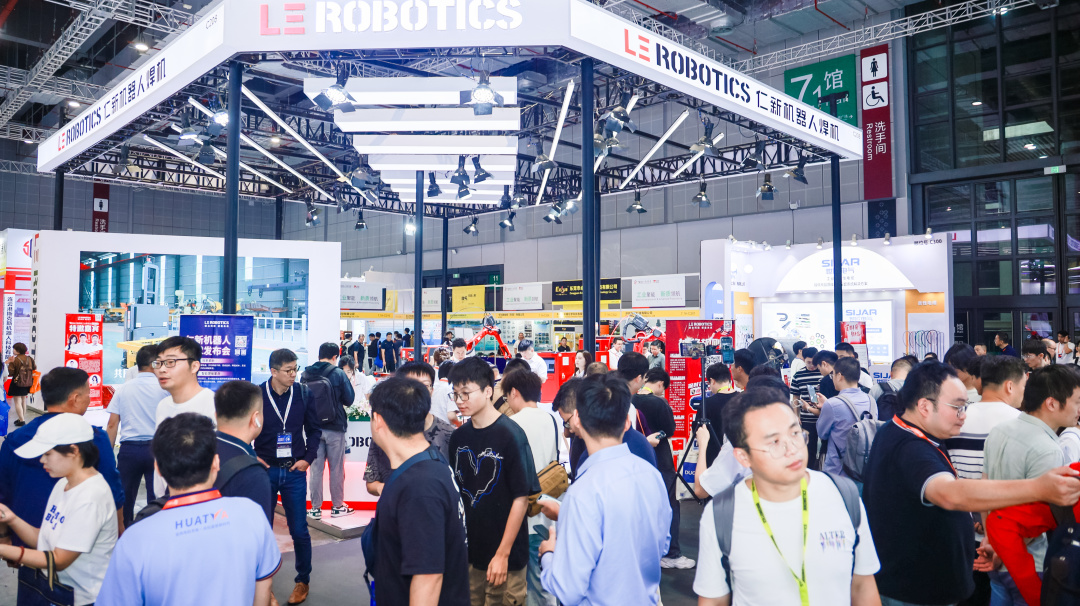

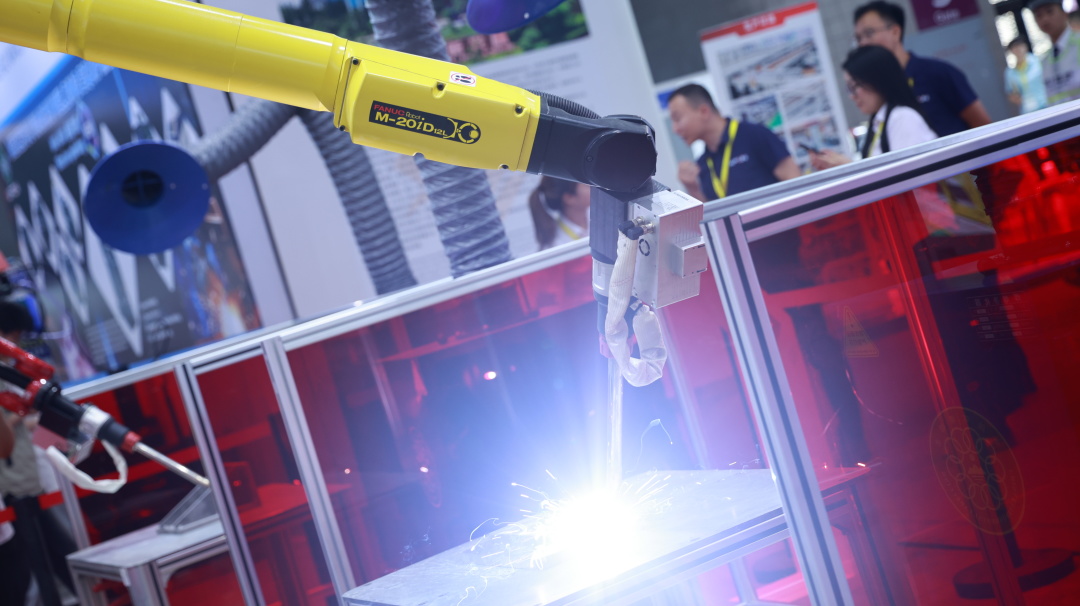

LE Robotics Welding Machines continues to make strides in technological innovation. In 2024, at the China International Industry Fair, the company's global debut of the "InstantSeam Welding" technology marked a significant leap for LE in welding technology. This technology involves pre-scanning the welding area of the workpiece with LE's intelligent 3D camera, accurately transmitting the weld seam position information to the mobile welding robot, using a high-precision binocular line laser 3D camera to collect point cloud data, and analyzing it with dedicated algorithms to accurately identify the weld seam and plan the optimal welding path. This technology supports various types of weld seams and provides real-time tracking and correction during the welding process to avoid welding deviation, establishing a complete closed-loop system that includes pre-weld guidance, in-process recognition, and post-weld tracking.

In addition, LE Robotics Welding Machines has invested hundreds of millions of yuan in the development of the "WeldOnMove" technology, specifically designed for large non-standard structural parts, providing a faster, more accurate, and smarter automated welding platform. Compared to traditional welding processes, this new technology has the advantage of continuous arc, significantly improving efficiency and quality. In practical applications, its operating speed has increased by 25%, and energy consumption has been reduced by 20%, creating an advanced benchmark for intelligent robot applications in the welding industry.

International Market Expansion: Enhancing Global Competitiveness

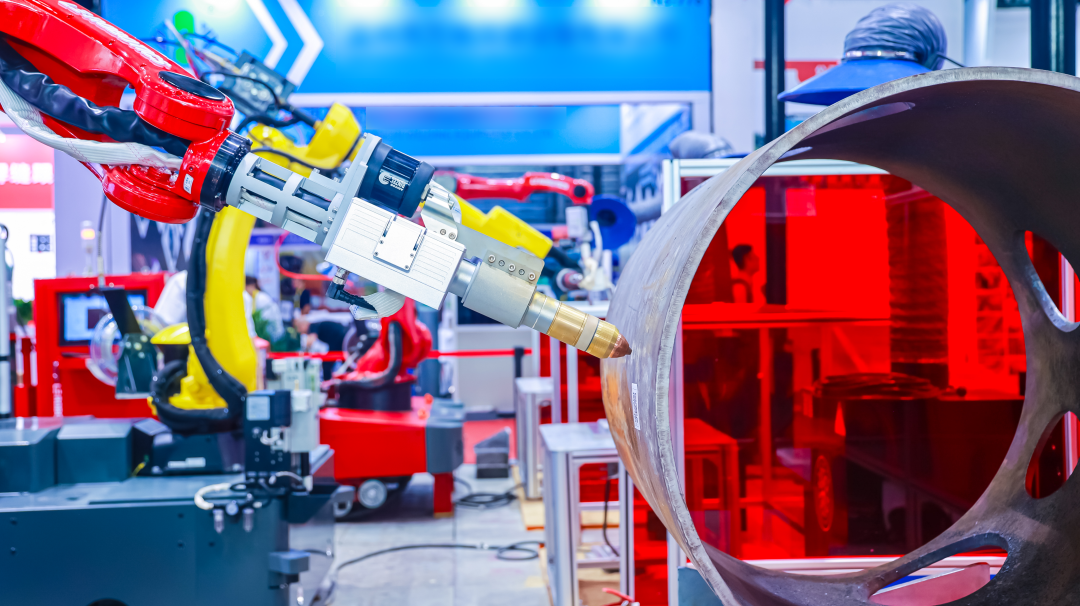

LE Robotics Welding Machines is closely following the trend of Chinese enterprises "going global" and actively expanding its global business footprint. In 2024, the company achieved significant growth in the field of industrial robot exports, especially in intelligent welding and cutting products, reflecting its increasing competitiveness and influence in the international market. With core technologies such as 3D vision technology, artificial intelligence (AI), SLAM autonomous navigation, and robotic control technology, LE Robotics Welding Machines provides automated solutions that meet the strict requirements of different materials and processes, satisfying the needs of industries such as large-scale engineering, oil and gas, infrastructure, environmental protection equipment, and steel construction.

In response to global market demands and growth potential, LE Robotics Welding Machines conducts in-depth analysis and formulates precise overseas expansion strategies. In North America, the rapid development of industries such as automotive, oil and gas, and construction has driven technological progress and automation trends in welding equipment. The European market, with its strong manufacturing industry and emphasis on renewable energy, automotive manufacturing, and infrastructure, has a growing demand for high-quality welding equipment. In the Asia-Pacific region, especially in China and India, the rapid development of industry and infrastructure is leading to a swift growth in the welding equipment market.

Faced with fierce competition in the international market, LE Robotics Welding Machines demonstrates unique advantages in performance, pricing, and after-sales service. The company's automated welding and cutting systems stand out and are widely used in the manufacturing of large non-standard structural parts. With advanced 3D vision and artificial intelligence technology, LE Robotics Welding Machines equips robots with the ability for autonomous navigation, path planning, and high-precision operations, enhancing production flexibility and efficiency.

Alliance Expansion: Global Strategic Deployment

LE Robotics Welding Machines, in its globalization strategy, deepened strategic cooperation and seized market opportunities by establishing branches in key regions in 2024. In North America, the establishment of a branch not only leveraged local market resources and technological advantages but also accelerated product localization to meet the demand for high-end intelligent manufacturing equipment. The establishment of a branch in Singapore not only covered the Southeast Asian market but also provided customers with more rapid service support. Additionally, LE Robotics Welding Machines recently signed a strategic cooperation agreement with SIASUN, jointly promoting industry innovation and development. These strategic moves have not only enhanced LE's global service capabilities but also strengthened the company's connection with international markets, expanding new horizons and possibilities for the company's future development.

The globalization layout of LE Robotics Welding Machines also includes the establishment of software research institutes in Shanghai, Beijing, and other locations, as well as the construction of R&D and production bases in Thailand, South Korea, and other regions, ensuring extensive coverage of the global market. Hu Haojie, the Executive President of LE Robotics Welding Machines, stated in public that the transformation and upgrading of the global manufacturing industry and the growing demand for automation and intelligent manufacturing have provided a broad market space for domestic industrial robots. "Through our international strategy, we not only bring advanced welding technology to the world but also continuously innovate and enhance product competitiveness through close collaboration with partners around the world, ensuring that LE always maintains a leading position in the international market."

Leveraging Policy Favors: Seizing Development Opportunities of the "Belt and Road" Initiative

LE Robotics Welding Machines actively responds to the national "Belt and Road" initiative by establishing a factory in Thailand, deepening international cooperation, and seizing development opportunities in the international market. This strategic layout not only obtains investment incentives and market access conveniences from the local government but also demonstrates the company's long-term commitment to the Southeast Asian market. The establishment of the Thai factory is a concrete manifestation of LE Robotics Welding Machines taking advantage of local investment policies and market access conveniences, which not only provides cost benefits for the company but also enhances its competitiveness in the Southeast Asian market.

The establishment of the Thai factory will enhance LE Robotics Welding Machines' flexibility and response capabilities in the Southeast Asian market, while reducing production costs and enhancing product competitiveness by utilizing local supply chain resources. This move not only creates jobs and promotes economic development locally, achieving a win-win situation, but also optimizes the global supply chain, making the Thai factory a regional center for LE Robotics Welding Machines to export products to surrounding and global markets.

According to Hu Haojie, the Executive President of LE Robotics Welding Machines, the establishment of the Thai factory is also a key step in optimizing the company's global supply chain. The company plans to use Thailand's geographical advantages to make it a regional center for exporting products to surrounding and global markets, thereby enhancing global market competitiveness and promoting the brand's transformation from "Made in China" to "Smart Made in China."

Thanks to policy support and market opportunities, LE Robotics Welding Machines' Thai factory will become an important fulcrum of its international strategy, providing a solid foundation for the company's long-term development and global market expansion.

International Vision Planning: Leading Chinese Intelligent Manufacturing to the Global Stage

In the global expansion strategy of LE Robotics Welding Machines, local operation and service are key to its success. The company has established a service network in multiple locations worldwide to ensure that customers receive timely technical support. This layout not only enhances the company's international influence but also enables it to quickly respond to customer needs and provide customized solutions.

In terms of service, LE Robotics Welding Machines offers a comprehensive customer experience that covers pre-sales consultation, in-sales support, and after-sales service. Before sales, the company provides business negotiations and expert reviews to ensure project feasibility. During sales, the company offers product debugging and training to ensure customers master the use of the products. After sales, the company commits to solving problems quickly to ensure customer satisfaction.

LE Robotics Welding Machines has also established a customer consultation center and repair services, offering frequently asked questions and online support to maintain long-term customer relationships and enhance satisfaction and loyalty.

In addition, the company's localization operations include a deep understanding of local markets and demand forecasting. By cooperating with local enterprises, the company continuously optimizes products and services to meet special needs. This strategy not only improves the company's international competitiveness but also brings practical value and convenience to global customers, demonstrating LE Robotics Welding Machines' commitment to customer promises and quality service.

LE Robotics Welding Machines' journey to go global is not only an inevitable choice for the company's development but also an important step for China's intelligent manufacturing to step onto the international stage. Hu Haojie, the Executive President of LE Robotics Welding Machines, stated that the company will continue to adhere to technological innovation and brand building, and by localizing operations and international cooperation, continuously improve the quality of products and services to provide global customers with higher-quality intelligent manufacturing solutions.

LE Robotics Welding Machines is embracing the new opportunities and challenges brought by globalization with an open attitude and a firm conviction.

——END——

Contact