June 10-12, 2025 – North America's most authoritative energy exhibition, the Canada Calgary International Energy Exhibition, commenced with over 300 enterprises from 20+ countries gathering at this industry summit.

LE Robotics | Canada (LE Robotics INC.)

made a stunning debut as the exclusive AI welding robotics specialist, showcasing cutting-edge Chinese intelligent manufacturing technology to the global energy equipment sector!

As the world's first AI industrial embodied welding solution provider certified with CSA North American mechanical and electrical safety standards, LE Robotics INC. leverages fully self-developed technologies including 3D vision, SLAM autonomous navigation, LE AI, and RX welding process database. It outperforms European and American competitors by 2-3 years in core metrics like trajectory precision, weld consistency, and operational efficiency. This certification breakthrough enables the North American market to tangibly experience the "Made in China" technological prowess and showcases China's advancements in AI welding technology.

The booth's dynamic demonstration centered on "Full-scenario Intelligent Welding Solutions" attracted in-depth coverage from multiple international industry media. Reports highlighted robotic trajectory precision and industry pain-point solutions, sparking industry-wide discussions on "Chinese welding robotics breaking into North America's high-end market." Professional institutions including Canada's Glacier Media and Alberta Engineers Association noted: "LE Robotics demonstrated outstanding technology and safety at this exhibition, with its AI welding system establishing a new paradigm for North American energy equipment manufacturing."

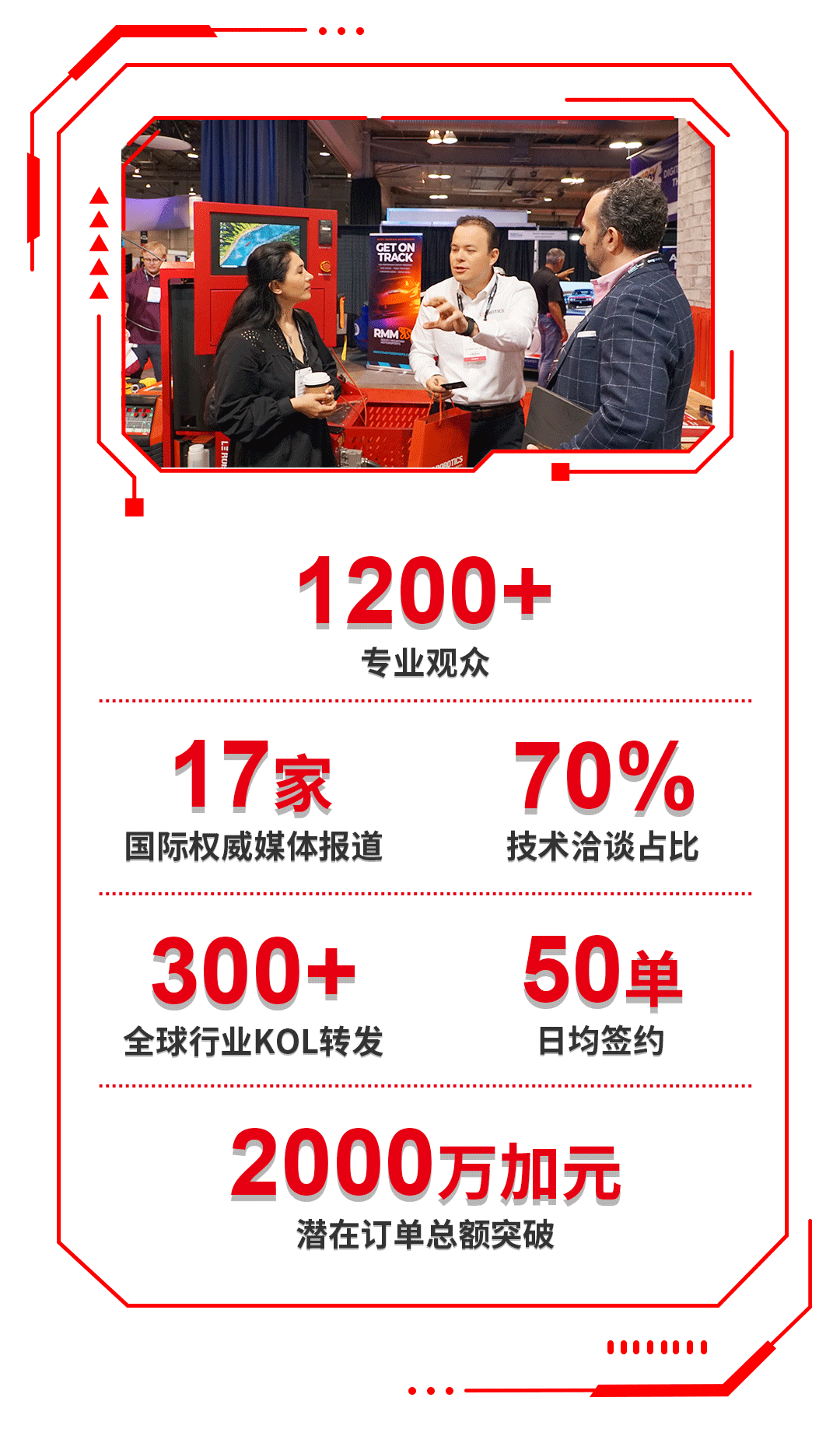

During the exhibition, LE Robotics INC. received 1,200+ professional visitors spanning oil/gas pipeline decision-makers, engineering machinery technical supervisors, senior welders, robotics engineers, and academic research teams. Approximately 50 daily signings were secured from oil pipeline and engineering machinery sectors.

Exhibited models including Maverick X and Maverick S have passed CSA Z432-24 & SPE-1000 dual-standard certification – becoming China's first welding robots to withstand ultra-low temperature, strong magnetism, and high dust extreme condition tests in North America.

These models demonstrate industrial welding capabilities across all scenarios:

●Achieved millimeter-level trajectory precision in pipeline flange circumferential welding.

● 3× efficiency gain versus manual welding.

●Validated multi-unit collaborative operations enabling single-operator oversight.

●Annual capacity: hundreds of kilometers of pipeline welding.

Through deep integration of 3D vision and LE AI algorithms, core functions include:

● Reverse modeling without programming

● Weld simulation prediction

● 3D drawing intelligent import

Enabling automated complex welding for oil/gas and engineering machinery sectors. Core algorithms were co-developed by researchers from Tsinghua University, Columbia University, and Harvard University, embodying LE Robotics' "Global Talent + China Scenarios" collaborative innovation.

LE Robotics INC. demonstrated "one robot replacing four welders" using localized data models aligned with Canadian labor costs and safety standards. In an Alberta natural gas pipeline project:

● Welding costs reduced by 47% per kilometer

● Project timeline shortened by 60%

● Achieved 189% ROI

This "technical parameters + commercial metrics" value proposition gained strong local recognition. At the exhibition, LE Robotics INC. demonstrated significant advantages in "arctic condition adaptability" and "cross-border after-sales response", establishing a "technical adaptation + local service" global competitive system tailored for Middle Eastern and North American clients. Multiple oil/gas EPC contractors affirmed LE Robotics' superior safety, efficiency, and energy-saving performance over existing European/American brands.

Aaron H.J. Hu

CEO, LE Robotics

We will establish a three-dimensional client follow-up system focusing on North American energy infrastructure leaders. Industry needs identified at the exhibition will accelerate intersecting line welding algorithm optimization. Our global exhibition roadmap includes Germany's Essen Welding and Chicago's Fabtech this year – delivering technologically advanced and commercially viable Chinese solutions for global energy infrastructure.

The technical recognition, media attention, and customer acclaim from this North American debut fully demonstrate LE Robotics' capabilities. From North America's energy heartland to the global industrial stage, LE Robotics participates in high-end international competition with self-developed intelligent welding technology, advancing Chinese welding technology globally and transforming industry competition dynamics.

——END——

Contact