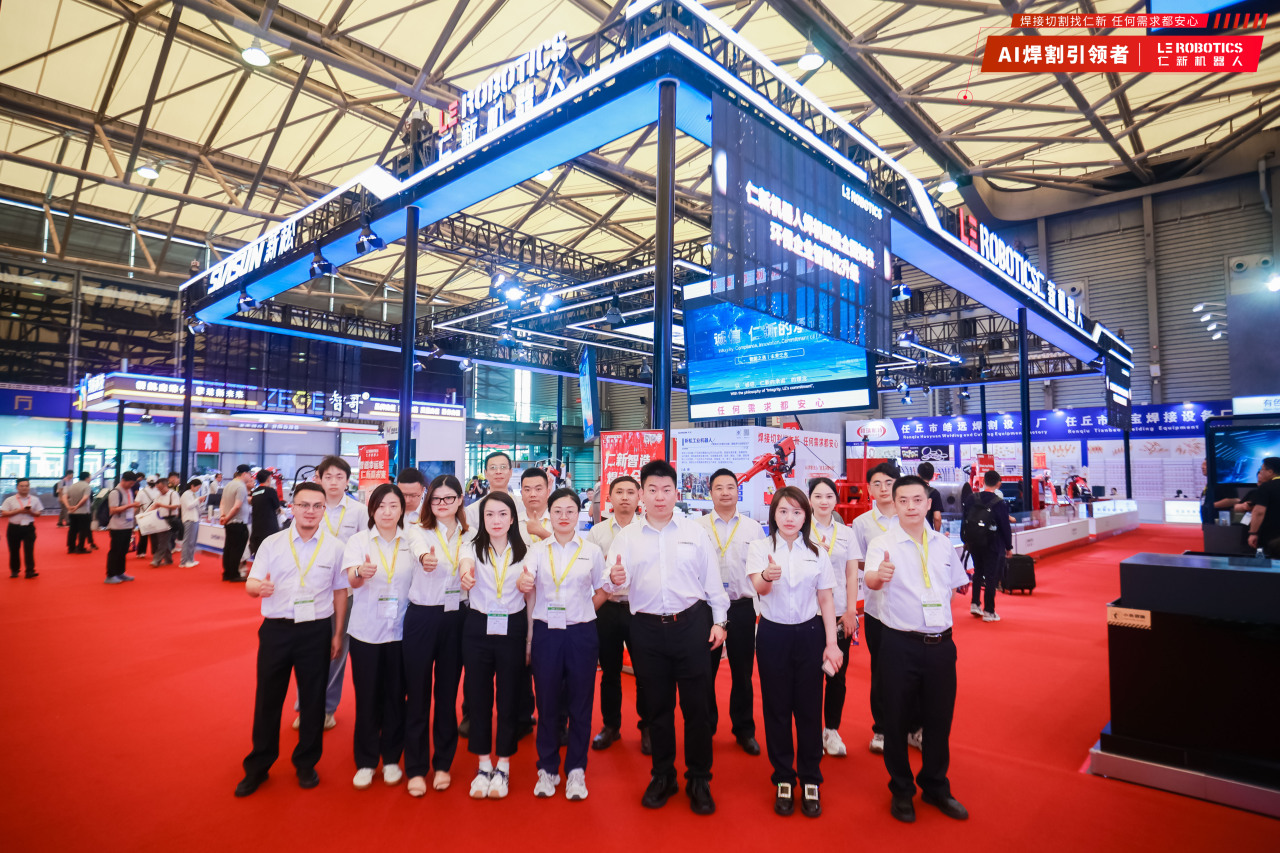

June 17-20, 2025 – The 28th Shanghai Essen Welding & Cutting Exhibition was grandly held at the Shanghai New International Expo Centre. This edition brought together over 800 top global exhibitors and attracted 30,000+ professional visitors from 100+ countries. Covering high-value sectors like machinery manufacturing, engineering equipment, energy equipment, shipbuilding, and steel structures, the exhibition showcased the extensive applications of welding and cutting technologies.

LE Robotics (Booth: E2702) debuted with three core products, demonstrating leadership in AI welding and cutting, particularly highlighting the newly launched L3.5 Intelligent Welding Technology and its industrial implementation capabilities.

The LE booth drew overwhelming crowds during the exhibition. International clients from Southeast Asia, Europe, Russia, Brazil, and other regions engaged in repeated discussions, showing strong interest in LE’s solutions.

Many overseas clients confirmed that LE Robotics effectively resolves critical challenges in non-standard structural welding. Clients praised our products for offering 'more convenient operation, stronger adaptability, and leading technology', proactively requesting detailed product configurations and procurement plans.

LE showcased three flagship AI welding robots, all equipped with the industry-first L3.5 "Intelligent Interactive AI Welding" System. This integrates four core technologies:

Reverse Modeling & Programming-Free Welding:

Scans workpieces via 3D cameras, constructs high-precision models, auto-identifies weld paths.

Weld Simulation & AI Parameter Optimization:

Simulates welding in virtual environments, predicts defects, auto-optimizes parameters.

3D Drawing Import & Auto-Programming:

Direct CAD file processing, intelligent process matching, reducing debugging costs by 80%.

Multi-Layer Welding Control:

Real-time molten pool monitoring and dynamic adjustments ensure consistent weld bead stacking.

Adapted for complex scenarios: oil pipelines, nuclear equipment, heavy machinery, shipbuilding, and steel structures—boosting efficiency while reducing energy consumption.

Investing in LE’s solutions delivers measurable returns:

Labor Cost Reduction:

Replaces manual welding in hazardous/complex environments, solving skilled-worker shortages.

Production Efficiency:

Shortens cycles through automated welding/cutting workflows.

Quality Improvement:

Ensures consistent weld quality, minimizing rework rates.

LE’s smart welding technology not only enhances production capabilities but also delivers long-term economic benefits and competitive advantages.

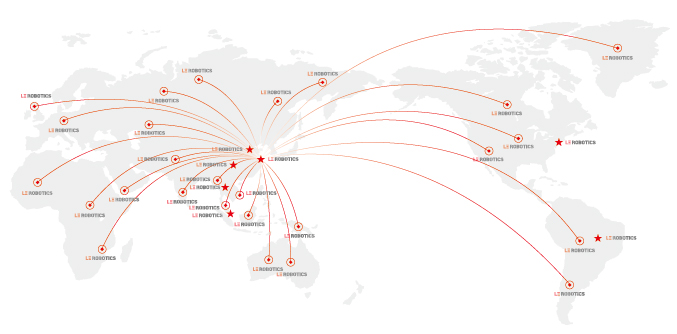

LE Robotics is expanding globally, partnering with multiple Fortune 500 companies. With branches and production bases in North America, Singapore, and Brazil, we strengthen our worldwide presence to provide agile, efficient services that accelerate smart manufacturing.

Growth never stops. We extend deep gratitude to partners, distributors, media teams, and exhibition organizers. Most importantly, we thank our clients for their trust. LE will advance alongside the industry, embracing an intelligent future together!

Contact